Gasket selection example with respect to different fluids, temperatures and pressures

■ Selection Procedure ■

Based on the sealing-target fluid and design condition (pressure, temperature), please confirm the applicable category from the selection chart, and verify the recommended gasket and usable gaskets in its category.

Fluids are categorized as below.

| ①water, hot water, water vapor | ⑥exhaust gas |

|---|---|

| ②crude oil, alcohol, animal and vegetable oils, heat transfer oil | ⑦flammable gas |

| ③solvent, weak acid, weak alkali | ⑧toxic gas |

| ④strong acid, strong alkali | ⑨oxygen |

| ⑤air, nitrogen gas, inert gas | ⑩cryogenic fluid |

■ Precautions ■

・The below selection list indicates the usable temperature and pressure range for each gasket, and it does not indicate the maximum usable temperature and pressure for each gasket.

・The recommended gasket is a representative gasket for each fluid, temperature and pressure condition, and not all of the other usable gaskets are listed.

・There are cases where the recommended gasket and usable gasket are different; therefore, please contact us for more information.

・The temperature for each pressure shall be: from -30°C to the stated temperature for ① to ⑨, and from the stated temperature to -30°C for ⑩.

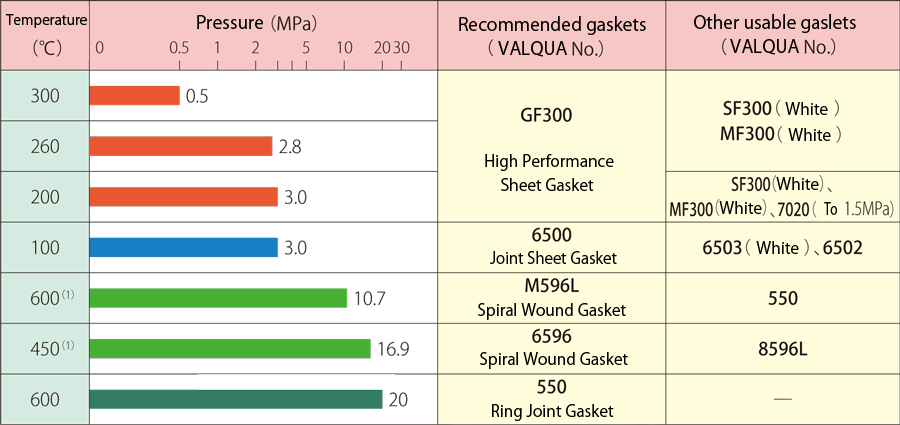

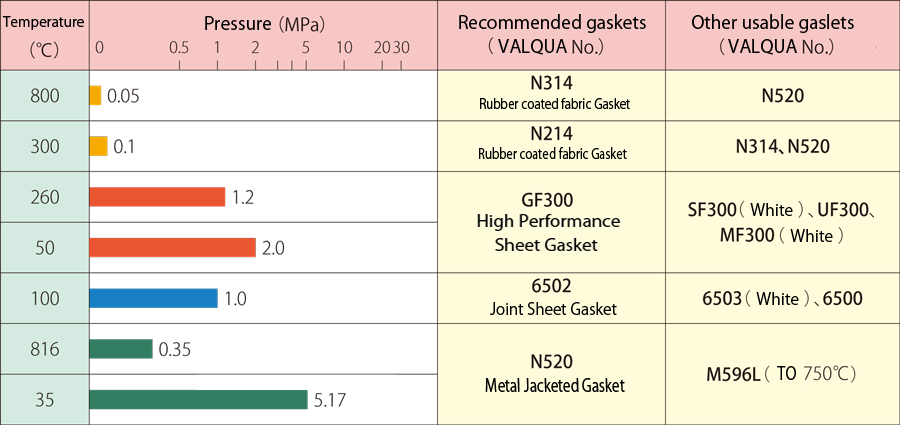

![]()

Point of View: There is no hardening with high performance sheet gaskets, and they are easy to use.

Point: Economical Compressed Non-Asbestos Fiber Sheet hardens at a temperature of 100°C or above; therefore, attention is needed for tightening control.

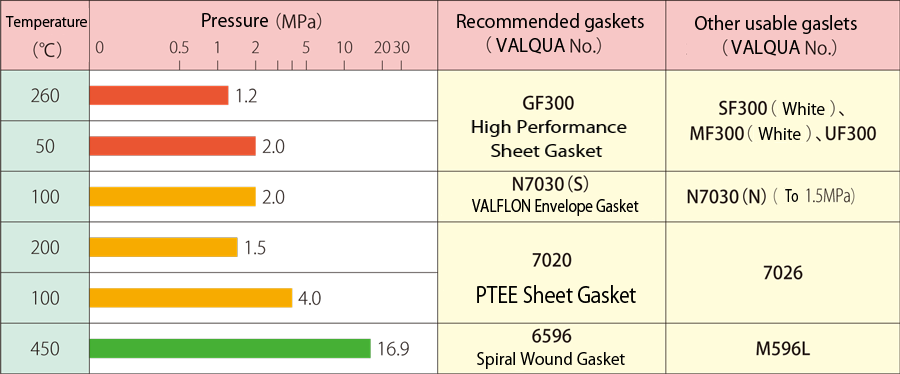

![]()

Point of View: Except for some fluids, fluid suitability is not a concern.

Point: An Economical Compressed Non-Asbestos Fiber Sheet hardens at a temperature of 100°C or above; therefore, attention is needed for tightening control.

Note (1) Excluding HTS. Please let us know if you are using HTS.

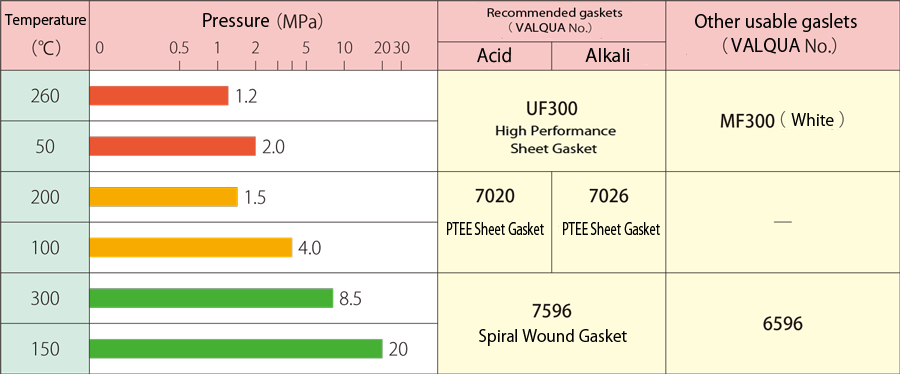

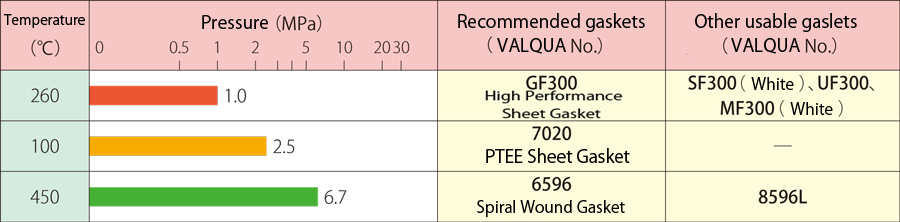

![]()

Point of View: PTFE-based and graphite-based gaskets with excellent chemical resistance are primarily selected.

Point: A High Performance Sheet Gasket can be used even at 260°C.

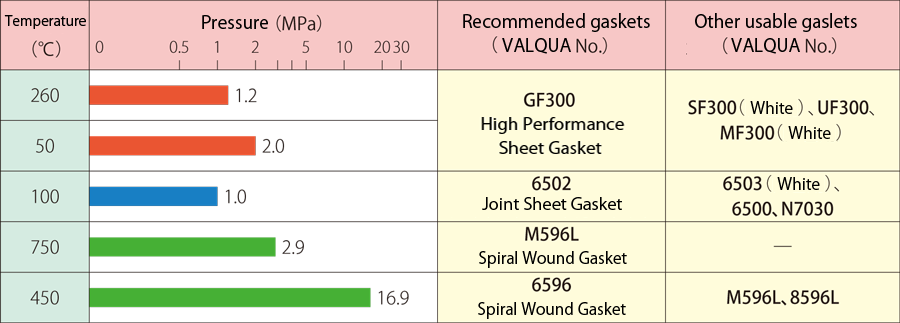

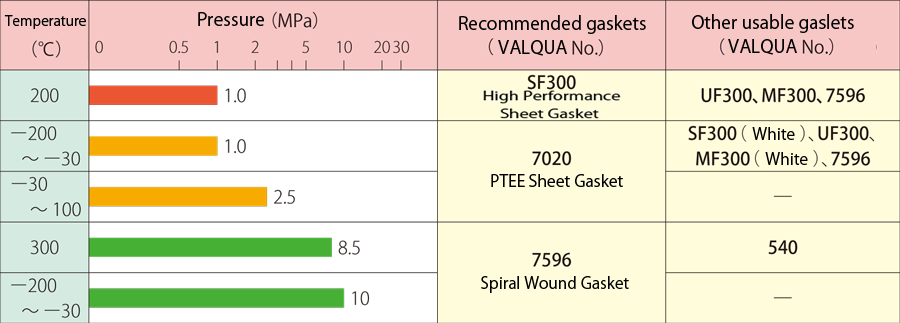

![]()

Point of View: PTFE-based gaskets with excellent chemical resistance are primarily selected.

Point: UF300 can be used for both high temperature strong acid and strong alkali.

![]()

Point of View: A Sheet Gasket is selected for utility pipes, and a Spiral Wound Gasket is selected for handling high pressure.

![]()

Point of View: A Sheet Gasket and a Semi-Metallic Gasket are used separately depending on the leakage allowance.

Point: A rubber coated fabric gasket can be used in areas where micro-pressure and a few leaks are acceptable.

![]()

Point of View: Gaskets with high gas sealing performance are primarily selected.

Point: A PTFE-based Sheet Gasket that is high in gas sealing performance or a spiral wound gasket is recommended.

![]()

Point of View: Gaskets with high gas sealing performance are mainly selected

Point: When considering reaction products, PTFE-based gasket is selected

![]()

Point of View: Gaskets using fluororesin, which is a non-combustible resin, are selected.

Point: In the case of using paste, new VALFLON paste is recommended when the temperature is 100°C or below.

![]()

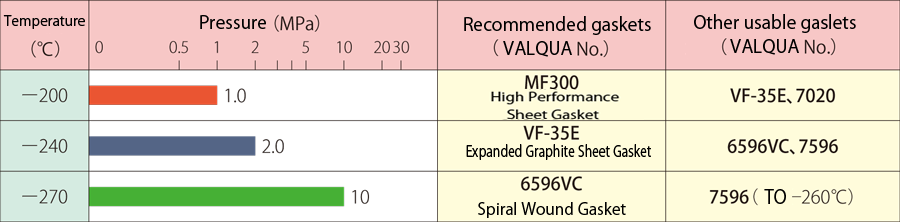

Point of View: Expanded graphite that does not become brittle as a material even at extremely low temperatures is selected.

Point: A High Performance Sheet Gasket can be used up to about -200°C.

■ Other items that shall be considered when making a selection ■

Gasket tightening surface pressure

Gasket dimensions

Combination of gasket and flange face

Flange face surface roughness

Precautions for various gaskets

■ Fluids that require attention when making a selection ■

| oxygen, combustion-supporting gus | We suggest to avoid the gasket made of flammable material and to use spiral shaped PTFE filler gasket, PTFE gasket, jacket shaped copper gasket, and flat metal gasket. |

| Polymerizable monomers | Some monomers like styrene monomer and vinyl chloride monomer may not use compressed fiber sheet gaske and PTFE gasket. Please choose spiral gasket with inner and outer ring and metal gasket. |

| fluid with slurry | Soft gasket may break and leak because of erosion. Please choose spiral gasket with inner and outer ring and metal gasket. |

| heat transfer oil | Compressed fiber sheet gaske cause leak because of degradation of rubber binder. Spiral shaped inorganic paper filler gasket has strong permeability and it may cause leak long time use. Please choose compressed fiber sheet gaske made of expanded graphite or spiral shaped expanded graphite filler gasket. But HTS cannnot use expanded graphite because which react. Please consult specially. |

| radioactive fluid | We do not suggest PTFE because it is weak in radiation. Expanded graphite has 1×106Gy radiation resistant. Please check the radiological dosage and choose. |