Metallic Serrated and Flat Gaskets

These gaskets are manufactured from cold rolled metal plate, and include flat gaskets made of metallic sheet which is processed into a specifield dimension and shape, and serrated gaskets with concetric grooves to improve sealing property.

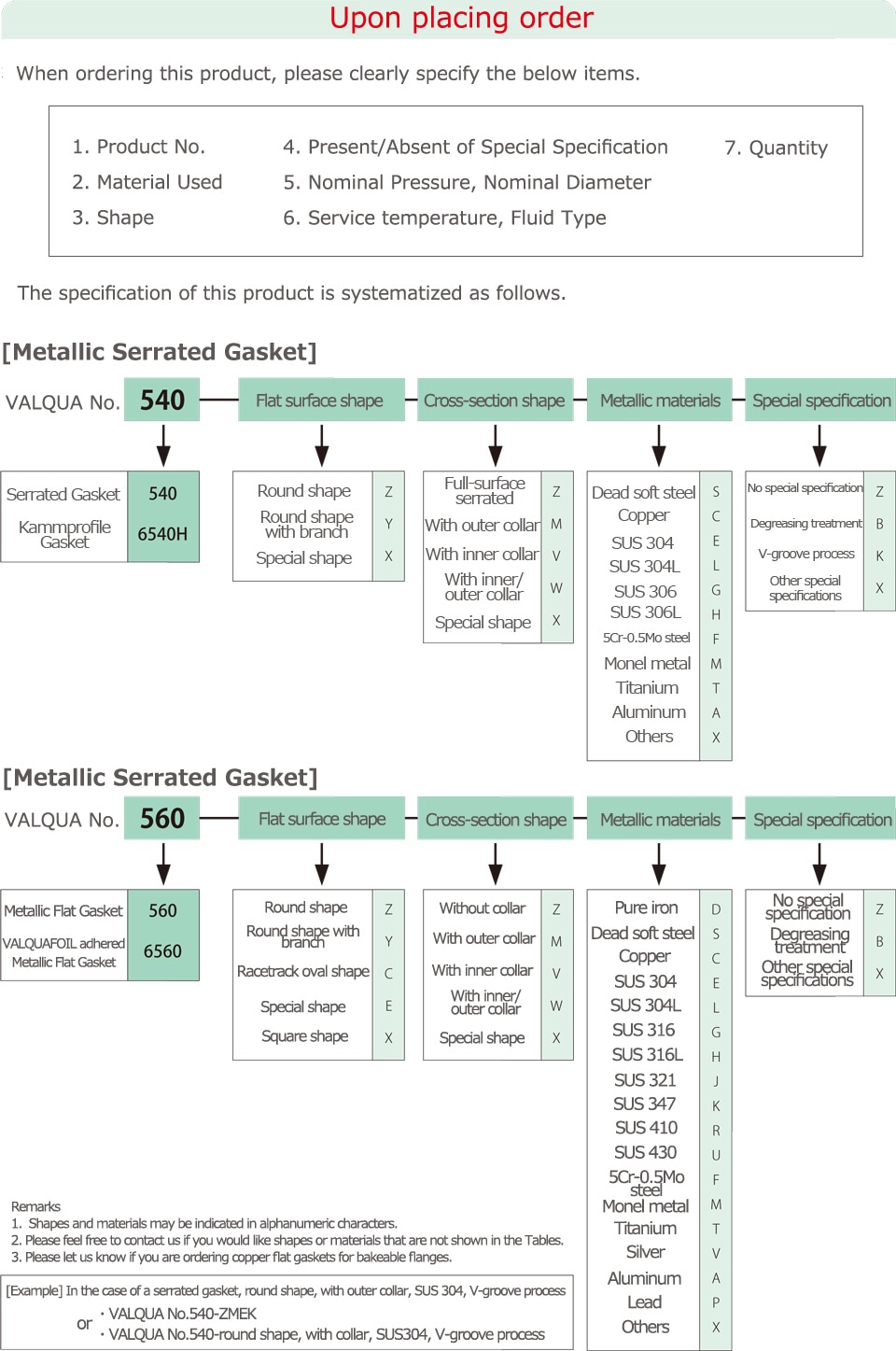

- VALQUA No.

- 540series

- Product name

- Metallic Serrated Gasket

- Features1

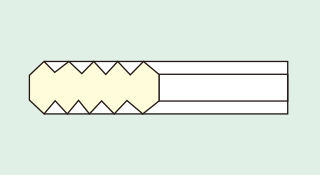

- Gasket made of metal sheet, grooved concentrically with saw-tooth cross section, and processed into a specified flat shape.

- Features2

- Products with any given dimensions can be manufactured based on information provided concerning material, shape and dimensions. Gaskets of various dimensions made of oxygen free copper are also available which are to be used for knife-edged shape flanges (ICF, UFC flanges, etc.) in use for semiconductor related facilities and vacuum equipment.

- Applicable fluids

- Water, Sea water, Hot water, Steam,Crude oil, Alcohol, Animal & vegetable oil, Heat transfer oilGeneral solvent, Weak acid, Weak alkali,Strong oxidizing acid, strong alkali,Air, Nitrogen gas, Inert gas,Exhaust gas,Inflammable gas,Poisonous,Oxygen,Extremely low temperature liquids,etc.

- Inappropriate fluid

- Dimensions

- Type

- Remarks

- 用途

- This gasket is used for hot and high-pressure vapor, the tower of a process line, a tub, a heat exchanger, autoclave, a valve bonnet, etc and applicable to raised face flange, grooved flange and male-female flange.