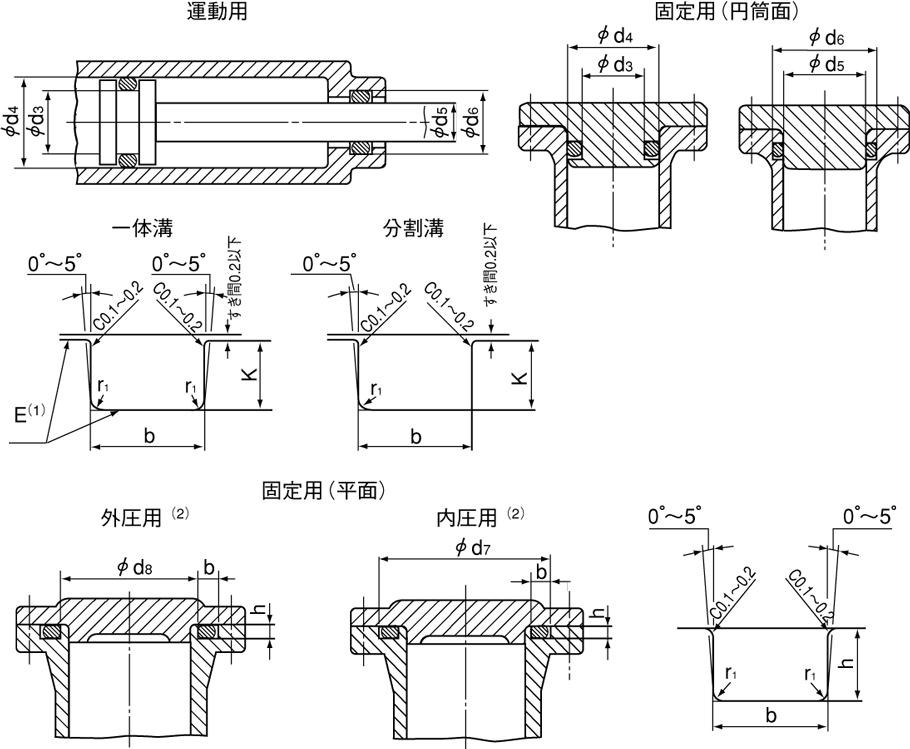

(3) 自動車用 (JASO固定用・運動用) Oリング溝部の形状および寸法(JASO F 404-96,参考)その1

溝部の形状・寸法

| 単位:mm |

| Oリングの | d5、d8 | d3 | d3、d5に対する 許容差 |

d4 | d6 | d7 | d4、d6に対する 許容差 |

b +0.25 0 |

r1 (最大) |

h (±0.05) |

E(1) (最大) |

|

| 呼び 内径 |

太さ d2 |

|||||||||||

| 3 | 1.9 | 3 | 3.1 | 0 -0.05 |

6 | 5.9 | 6.3 | +0.05 0 |

2.5 | 0.4 | 1.4 | 0.05 |

| 4 | 4 | 4.1 | 7 | 6.9 | 7.3 | |||||||

| 5 | 5 | 5.1 | 8 | 7.9 | 8.3 | |||||||

| 6 | 6 | 6.1 | 9 | 8.9 | 9.3 | |||||||

| 7 | 7 | 7.1 | 10 | 9.9 | 10.3 | |||||||

| 8 | 8 | 8.1 | 11 | 10.9 | 11.3 | |||||||

| 9 | 9 | 9.1 | 12 | 11.9 | 12.3 | |||||||

| 10 | 10 | 10.1 | 13 | 12.9 | 13.3 | |||||||

| 11.2 | 11.2 | 11.3 | 0 -0.06 |

14.2 | 14.1 | 14.4 | +0.06 0 |

|||||

| 12.5 | 12.5 | 12.6 | 15.5 | 15.4 | 15.7 | |||||||

| 13.2 | 13.2 | 13.3 | 16.2 | 16.1 | 16.4 | |||||||

| 14 | 14 | 14.1 | 17 | 16.9 | 17.2 | |||||||

| 15 | 15 | 15.1 | 18 | 17.9 | 18.2 | |||||||

| 16 | 16 | 16.1 | 19 | 18.9 | 19.2 | |||||||

| 17 | 17 | 17.1 | 20 | 19.2 | 20.2 | |||||||

| 18 | 18 | 18.1 | 21 | 20.9 | 21.2 | |||||||

| 19 | 19 | 19.1 | 22 | 21.9 | 22.2 | |||||||

| 20 | 20 | 20.1 | 23 | 22.9 | 23.2 | |||||||

| 21.2 | 21.2 | 21.3 | 24.2 | 24.1 | 24.4 | |||||||

| 22.4 | 1.9 | 22.4 | 22.5 | 0 -0.08 |

25.4 | 25.3 | 25.5 | +0.08 0 |

2.5 | 0.4 | 1.4 | 0.05 |

| 23.6 | 23.6 | 23.7 | 26.6 | 26.5 | 26.7 | |||||||

| 25 | 25 | 25.1 | 28 | 27.9 | 28.1 | |||||||

| 26.5 | 26.5 | 26.6 | 29.5 | 29.4 | 29.6 | |||||||

| 28 | 28 | 28.1 | 31 | 30.9 | 31.1 | |||||||

| 30 | 30 | 30.1 | 33 | 32.9 | 33.1 | |||||||

| 31.5 | 31.5 | 31.6 | 34.5 | 32.9 | 34.6 | |||||||

| 33.5 | 33.5 | 33.6 | 36.5 | 36.4 | 36.6 | |||||||

| 35.5 | 35.5 | 35.6 | 38.5 | 38.4 | 38.6 | |||||||

| 10 | 2.4 | 10 | 10.2 | 0 -0.06 |

14 | 13.8 | 14.1 | +0.06 0 |

3.2 | 1.8 | ||

| 11.2 | 11.2 | 11.4 | 15.2 | 15 | 15.3 | |||||||

| 12.5 | 12.5 | 12.7 | 16.5 | 16.3 | 16.6 | |||||||

| 13.2 | 13.2 | 13.4 | 17.2 | 17 | 17.3 | |||||||

| 14 | 14 | 14.2 | 18 | 17.8 | 18.1 | |||||||

| 15 | 15 | 15.2 | 19 | 18.8 | 19.1 | |||||||

| 16 | 16 | 16.2 | 20 | 19.8 | 20.1 | |||||||

| 17 | 17 | 17.2 | 21 | 20.8 | 21.1 | |||||||

| 18 | 18 | 18.2 | 22 | 21.8 | 22.1 | |||||||

| 19 | 19 | 19.2 | 23 | 22.8 | 23.1 | |||||||

| 20 | 20 | 20.2 | 24 | 23.8 | 24.1 | |||||||

| 21 | 21 | 21.2 | 25 | 24.8 | 25.1 | |||||||

| 22.4 | 22.4 | 22.6 | 0 -0.08 |

26.4 | 26.2 | 26.4 | +0.08 0 |

|||||

| 23.6 | 23.6 | 23.8 | 27.6 | 27.4 | 27.6 | |||||||

| 25 | 25 | 25.2 | 29 | 28.8 | 29 | |||||||

| 26.5 | 26.5 | 26.7 | 30.5 | 30.3 | 30.5 | |||||||

| 28 | 28 | 28.2 | 32 | 31.8 | 32 | |||||||

| 30 | 30 | 30.2 | 34 | 33.8 | 34 | |||||||

| 31.5 | 31.5 | 31.7 | 35.5 | 35.3 | 35.5 | |||||||

| 33.5 | 33.5 | 33.7 | 37.5 | 37.3 | 37.5 | |||||||

| 35.5 | 35.5 | 35.7 | 39.5 | 39.3 | 39.5 | |||||||

| 37.5 | 37.5 | 37.7 | 41.5 | 41.3 | 41.5 | |||||||

| 40 | 40 | 40.2 | 44 | 43.8 | 44 | |||||||

| 42.5 | 42.5 | 42.7 | 46.5 | 46.3 | 46.5 | |||||||

| 45 | 45 | 45.2 | 49 | 48.8 | 49 | |||||||

| 47.5 | 47.5 | 47.7 | 51.5 | 51.3 | 51.5 | |||||||

| 50 | 50 | 50.2 | 54 | 53.8 | 54 | |||||||

| 53 | 53 | 53.2 | 0 -0.10 |

57 | 56.8 | 57 | +0.10 0 |

|||||

| 56 | 56 | 56.2 | 60 | 59.8 | 60 | |||||||

| 60 | 60 | 60.2 | 64 | 63.8 | 64 | |||||||

| 63 | 63 | 63.2 | 67 | 66.8 | 67 | |||||||

| 67 | 67 | 67.2 | 71 | 70.8 | 71 | |||||||

| 71 | 71 | 71.2 | 75 | 74.8 | 75 | |||||||

| 25 | 3.1 | 25 | 25.3 | 0 -0.08 |

30.3 | 30.1 | 30.3 | +0.08 0 |

4.3 | 0.5 | 2.4 | 0.06 |

| 30 | 30 | 30.3 | 35.3 | 35.1 | 35.3 | |||||||

| 35 | 35 | 35.3 | 40.3 | 40.1 | 40.3 | |||||||

| 40 | 40 | 40.3 | 45.3 | 45.1 | 45.3 | |||||||

| 45 | 45 | 45.3 | 50.3 | 50.1 | 50.3 | |||||||

| 50 | 50 | 50.3 | 0 -0.10 |

55.3 | 55.1 | 55.3 | +0.10 0 |

|||||

| 55 | 55 | 55.3 | 60.3 | 60.1 | 60.3 | |||||||

| 60 | 60 | 60.3 | 65.3 | 65.1 | 65.3 | |||||||

| 65 | 65 | 65.3 | 70.3 | 70.1 | 70.3 | |||||||

| 70 | 70 | 70.3 | 75.3 | 75.1 | 75.3 | |||||||

内圧のかかる場合はOリングの外周が溝の外壁に密着するように設計し、 外圧がかかる場合には、反対にOリングの

内周が溝の内壁と密着するように設計する。