Lining Bellows

- VALFLON Cut Bellows

-

- VALFLON Molded Bellows

-

| No. |

7803-1

7803-2

7803-3

7803-4 |

- Metal Coated VALFLON Bellows

-

■ VALFLON Cut Bellows (7801)

This is a bellows in which a PTFE sleeve is machined and a flange is attached to both ends. The spring constant is small, and the threads per inch can be set freely.

This product is used for an expansion and contraction joint such as of PTFE lining pipes, glass lining pipes and carbon lining pipes.

■ VALFLON Molded Bellows (7803‐1, ‐2, ‐3, ‐4)

This is a bellows in which a PTFE hose is fabricated.

No.7803-1...Basic shape

No.7803-2...Basic shape, control ring material

No.7803-3...With external cylinder

No.7803‐4...Thick wall type

This product is used as a joint for the absorption of axis displacement.

No.7803-1...General-purpose

No.7803-2...General-purpose, with control ring

No.7803-3...Pressure-resistant, for pressure resistance

No.7803-3...Pressure-resistant, for vacuum

■ Metal Coated VALFLON Bellows (7806‐1, ‐2, ‐3)

This is a PTFE molded bellows coated with thin metallic plate.

No.7806-1...With sleeve

No.7806-2...Without sleeve

No.7806-3...With inner without sleeve

This product is used as a pipe joint requiring pressure and heat resistance properties.

No.7806-3 is suitable for a vacuum.

■ Product name and applications

| VALQUA No. |

Product name |

Applications |

| ▶ 7801 |

Cut bellows |

Mainly used for expansion and contraction joints. |

| ▶ 7803-1 |

Molded bellows |

Used as a pipe joint for absorption of axis displacement. General use. |

| ▶ 7803-2 |

Molded bellows (with control ring) |

Used as a pipe joint for absorption of axis displacement. General use. |

| ▶ 7803-3 |

Molded bellows (with external cylinder) |

Used as a pipe joint for absorption of axis displacement. For heat and pressure resistance. |

| ▶ 7803-4 |

Molded bellows (thick wall type) |

Used as a pipe joint for absorption of axis displacement. Can be used also for heat resistance, pressure resistance and vacuum. |

| ▶ 7806-1 |

Metal coated bellows (with sleeve) |

Used as a pipe joint requiring pressure and heat resistance properties. |

| ▶ 7806-2 |

Metal coated bellows (without sleeve) |

Used as a pipe joint requiring pressure and heat resistance properties. |

| ▶ 7806-3 |

Metal coated bellows (with inner without sleeve) |

Used as a pipe joint requiring pressure and heat resistance properties. Can be used also for vacuum. |

■ Selection criteria

| Heat resistance |

Cold resistance |

Chemicals resistance |

Penetration resistance |

Displacement absorption |

Low counterforce |

Flexibility |

Flexing life |

Lightness |

(2)F/S |

Stress dispersion |

(3)SCC resistance |

| Shaft |

Right angle

(axial difference) |

Angle |

Vibration |

| △ |

○ |

◎ |

○ |

◎ |

○ |

◎ |

◎ |

◎ |

◎ |

○ |

◎ |

× |

× |

○ |

| ○ |

◎ |

◎ |

△ |

○ |

◎ |

○ |

◎ |

◎ |

◎ |

◎ |

◎ |

× |

△ |

○ |

| ○ |

○ |

◎ |

○ |

× |

× |

× |

△ |

○ |

○ |

○ |

△ |

× |

△ |

○ |

| ◎ |

○ |

◎ |

◎ |

× |

× |

× |

× |

○ |

○ |

○ |

△ |

○ |

◎ |

○ |

| ◎ |

◎ |

◎ |

◎ |

◎ |

◎ |

◎ |

○ |

○ |

○ |

○ |

○ |

○(1) |

○ |

◎ |

| ◎ |

◎ |

◎ |

△ |

○ |

△ |

○ |

× |

△ |

× |

× |

△ |

○ |

◎ |

× |

| ◎ |

◎ |

◎ |

△ |

○ |

△ |

○ |

× |

△ |

× |

× |

○ |

○ |

◎ |

× |

| ◎ |

◎ |

◎ |

△ |

× |

△ |

× |

× |

× |

× |

× |

○ |

○ |

◎ |

× |

Note:

(1) If attached with external cylinder

(2) Fire-safe

(3) Stress corrosion cracking

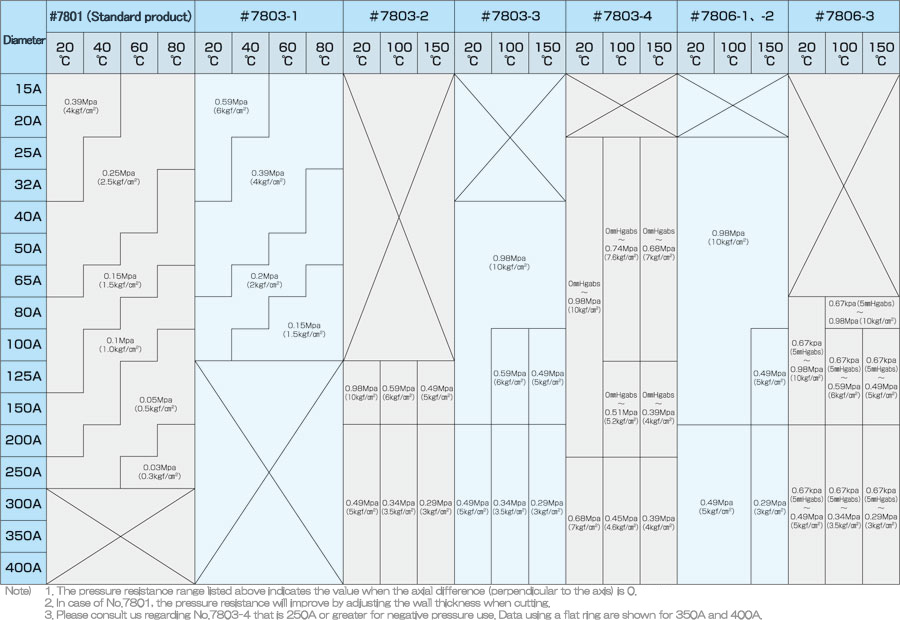

■ Bellows scope of application

■ Precautions

Precautions for safe use and handling

(A) Avoid mounting in excess of the allowable expansion and contraction because it may affect the life.

(B) It is also dangerous to set up when the limit bolt is removed. In particular, please consult us if a large axial difference or angular displacement is necessary.

(C) Fix the pipe in front of and behind the bellows.

(D) Set in regular intervals when the number of attached places will be two places due to the amount of expansion and contraction.

(E) When setting on a dangerous fluid pipe, take safety measures by attaching a protective cover to the bellows or by alternative means.

(F) When using a bellows joint for vibration absorption, attach the bellows to the equipment as close as possible, and strongly fix the pipe on the opposite side of the equipment in a place that is as close as possible to the bellows.

Precautions for safe storage

(A) Always attach a cover flange that protects the flare part before storage.

(B) Make sure to lock the bellows interface at free length and that rain water and the like that contain salt content do not fall on it. Also be particularly careful so that the VALFLON bellows is not damaged from the outside.