VALQUATIGHT GASKET

Spiral Wound Gaskets use Non-Asbestos inorganic paper, VALQUAFOIL™ (expanded graphite) and VALFLON™ (PTFE) tape as filler materials, and exhibit good elasticity by means of a V-shaped hoop.

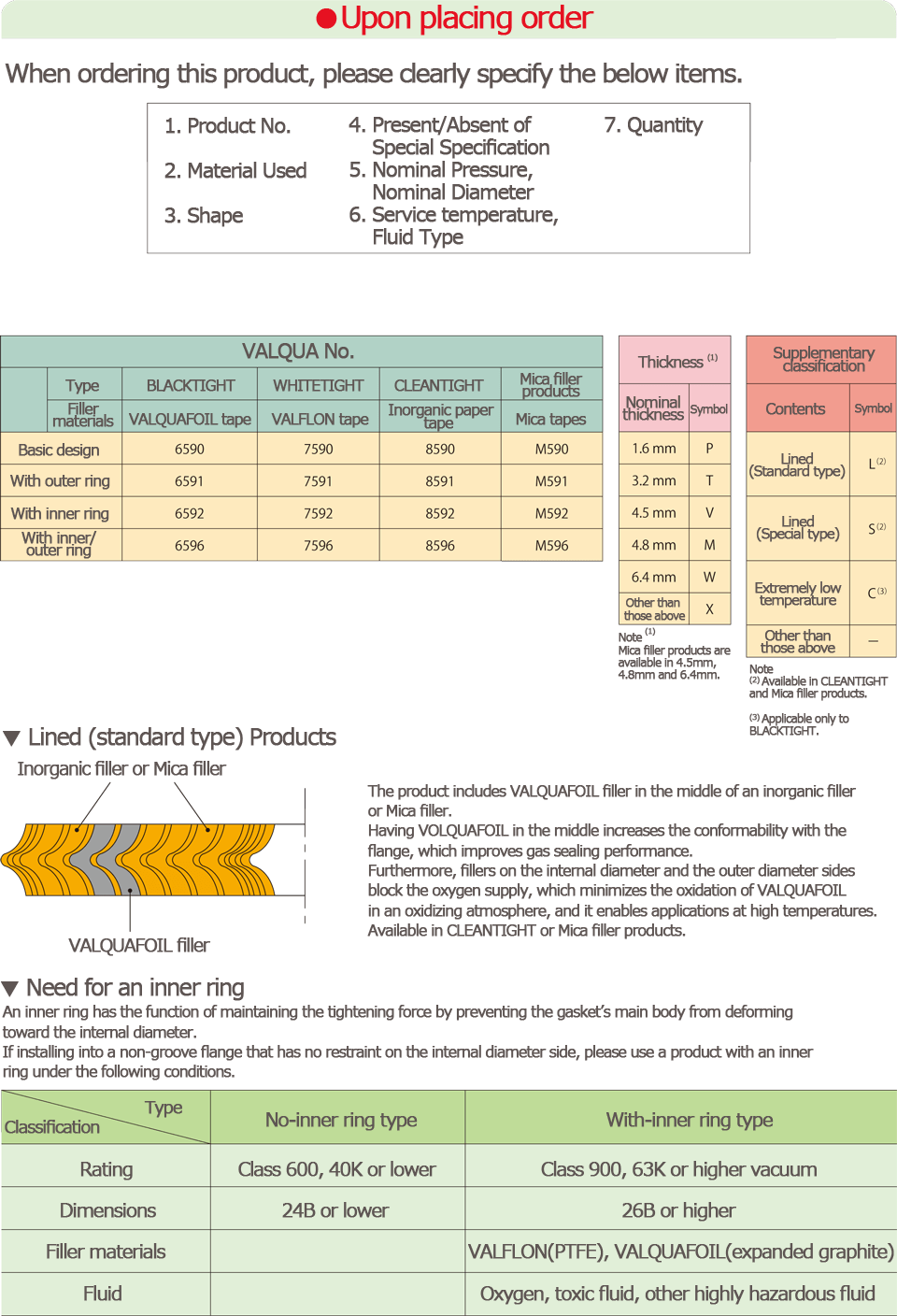

- VALQUA No.

- 6590

- Product name

- BLACKTIGHT (basic design)

- Features1

- Spiral wound gasket using VALQUAFOIL tape applied as filler material

- Features2

- The basic-shape gasket is used for male-female and tongue and groove flanges, bonnets of valves, as well as covers for pressure vassels, towers, and tanks. It only requires a narrow width, and safe for use under high pressure.

- Features3

- Excellent airtightness greatly improves sealing performance against gas in general and vacuum.

- Features4

- Excellent response to heat and pressure cycles reduces the frequency of retightening.

- Features5

- They also have excellent radiation resistance (products complying nuclear power specifications are available).

- Applicable fluids

- Water, Sea water, Hot water, Steam,Crude oil, Alcohol, Animal & vegetable oil, Heat transfer oil,General solvent, Weak acid, Weak alkali,Strong oxidizing acid, strong alkali,Air, Nitrogen gas, Inert gas,Exhaust gas,Inflammable gas,Poisonous,Extremely low temperature liquids,

- Inappropriate fluid

- Oxidizing acids such as hot, concentrated sulfuric acid, concentrated nitric acid and oxygen.

- Application

- In particular best suited as gaskets for use handling high temperature & high pressure steam (except HTS), as well as very low temperature fluids such as LNG, liquid nitrogen and liquid hydrogen.