Shrinkable Tube

- VALQUA No.

- ZSGB

ZSMB - Product name

- Shrinkable Tube

- Product features

- The Shrinkable Tube adds functionality to a shrinking target object by shrinking in a radial direction by heating. All kinds of functionalities, such as insulation properties, mold releasing properties and protective functions, are given depending on the material and application.

In addition to our standard size lineup, at VALQUA we take custom orders. We also handle many kinds of materials, centering on our fluororesin.

PTFE

PFA

FEP

PEEK

ETFE

PET

■ Size chart

| Millimeter dimensions |

| SW(Standard wall thickness) | TW(Thin wall) | LW(Ultra-thin wall) | |||||||||

| Nominal Size |

Inner diameter before shrinking (Minimum value) |

Inner diameter after shrinking (Maximum value) |

Standard wall thickness after shrinking - tolerance | Nominal Size |

Inner diameter before shrinking (Minimum value) |

Inner diameter after shrinking (Maximum value) |

Standard wall thickness after shrinking - tolerance | Nominal Size |

Inner diameter before shrinking (Minimum value) |

Inner diameter after shrinking (Maximum value) |

Standard wall thickness after shrinking - tolerance |

| 30 | 0.86 | 0.38 | 0.23±.05 | 30 | 0.86 | 0.38 | 0.23±.05 | 30 | 0.86 | 0.38 | 0.15±.05 |

| 28 | 0.96 | 0.46 | 0.23±.05 | 28 | 0.96 | 0.46 | 0.23±.05 | 28 | 0.96 | 0.46 | 0.15±.05 |

| 26 | 1.17 | 0.56 | 0.25±.05 | 26 | 1.17 | 0.56 | 0.25±.05 | 26 | 1.17 | 0.56 | 0.15±.05 |

| 24 | 1.27 | 0.69 | 0.3±.05 | 24 | 1.27 | 0.69 | 0.25±.05 | 24 | 1.27 | 0.64 | 0.15±.05 |

| 22 | 1.4 | 0.81 | 0.3±.05 | 22 | 1.4 | 0.81 | 0.3±.08 | 22 | 1.4 | 0.79 | 0.15±.05 |

| 20 | 1.52 | 0.99 | 0.41±.08 | 20 | 1.52 | 0.99 | 0.3±.08 | 20 | 1.52 | 0.97 | 0.15±.05 |

| 19 | 1.65 | 1.09 | 0.41±.08 | 19 | 1.65 | 1.09 | 0.3±.08 | 19 | 1.65 | 1.09 | 0.15±.05 |

| 18 | 1.93 | 1.24 | 0.41±.08 | 18 | 1.93 | 1.24 | 0.3±.08 | 18 | 1.93 | 1.17 | 0.15±.05 |

| 17 | 2.16 | 1.37 | 0.41±.08 | 17 | 2.16 | 1.37 | 0.3±.08 | 17 | 2.16 | 1.37 | 0.15±.05 |

| 16 | 2.36 | 1.55 | 0.41±.08 | 16 | 2.36 | 1.55 | 0.3±.08 | 16 | 2.36 | 1.45 | 0.15±.05 |

| 15 | 2.79 | 1.7 | 0.41±.08 | 15 | 2.79 | 1.7 | 0.3±.08 | 15 | 2.79 | 1.6 | 0.15±.05 |

| 14 | 3.05 | 1.83 | 0.41±.08 | 14 | 3.05 | 1.83 | 0.3±.08 | 14 | 3.05 | 1.83 | 0.2±.05 |

| 13 | 3.56 | 2.03 | 0.41±.08 | 13 | 3.56 | 2.03 | 0.3±.08 | 13 | 3.56 | 2.03 | 0.2±.05 |

| 12 | 3.81 | 2.26 | 0.41±.08 | 12 | 3.81 | 2.26 | 0.3±.08 | 12 | 3.81 | 2.26 | 0.2±.05 |

| 11 | 4.32 | 2.57 | 0.41±.08 | 11 | 4.32 | 2.57 | 0.3±.08 | 11 | 4.32 | 2.51 | 0.2±.05 |

| 10 | 4.85 | 2.84 | 0.41±.08 | 10 | 4.85 | 2.84 | 0.3±.08 | 10 | 4.85 | 2.79 | 0.2±.05 |

| 9 | 5.21 | 3.15 | 0.51±.10 | 9 | 5.21 | 3.15 | 0.38±.10 | 9 | 5.21 | 3.1 | 0.2±.05 |

| 8 | 6.1 | 3.58 | 0.51±.10 | 8 | 6.1 | 3.58 | 0.38±.10 | 8 | 6.1 | 3.53 | 0.2±.05 |

| 7 | 6.86 | 4.01 | 0.51±.10 | 7 | 6.86 | 4.01 | 0.38±.10 | 7 | 6.86 | 3.91 | 0.2±.05 |

| 6 | 7.67 | 4.52 | 0.51±.10 | 6 | 7.67 | 4.52 | 0.38±.10 | 6 | 7.67 | 4.37 | 0.25±.08 |

| 5 | 8.13 | 5.03 | 0.51±.10 | 5 | 8.13 | 5.03 | 0.38±.10 | 5 | 8.13 | 4.88 | 0.25±.08 |

| 4 | 9.4 | 5.69 | 0.51±.10 | 4 | 9.4 | 5.69 | 0.38±.10 | 4 | 9.4 | 5.44 | 0.25±.08 |

| 3 | 9.91 | 6.32 | 0.51±.10 | 3 | 9.91 | 6.32 | 0.38±.10 | 3 | 9.91 | 6.12 | 0.25±.08 |

| 2 | 10.92 | 7.06 | 0.51±.10 | 2 | 10.92 | 7.06 | 0.38±.10 | 2 | 10.92 | 6.86 | 0.25±.08 |

| 1 | 11.43 | 7.9 | 0.51±.10 | 1 | 11.43 | 7.9 | 0.38±.10 | 1 | 11.43 | 7.65 | 0.25±.08 |

| 0 | 11.94 | 8.81 | 0.51±.10 | 0 | 11.94 | 8.81 | 0.38±.10 | 0 | 11.94 | 8.81 | 0.3±.08 |

Packaging: Please refer to the “Technical Data” for details.

Unless particularly specified, the color will be a natural color. If desired, you can choose from either Pantone colors or Zeus standard colors.

Compatible specification: AMS-STL-23053/12, UL File# E64007/CSA File# 082582

■ Precautions for safe shrink processing

1. Please check that the working space is sufficiently ventilated before starting the shrinking processing.

Note: The cracked gas occurring during work may cause a feeling of nausea or dizziness.

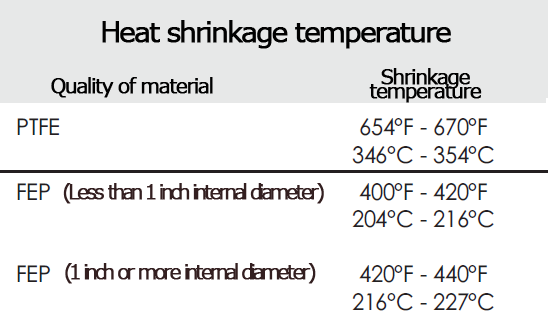

2. Please check that the coated target object can resist the heat shrinking temperature. (Refer to chart)

3. Heat may be absorbed by the coated object (especially if the coated object is metallic). In such a case, we recommend preheating the coated object before processing.

4. The tube will shrink at least 20% due to shrinking processing. If the shrinkage in the radial direction is limited too much, the vertical length of the tube will change, and there will be a stronger tendency for cracks to occur. When carrying out shrinking processing, shrink the tube at least 20%. If the shrinking in the radial direction is restricted, then it will trigger a change in the length direction, and thereby become a cause for processing defects such as a crack.

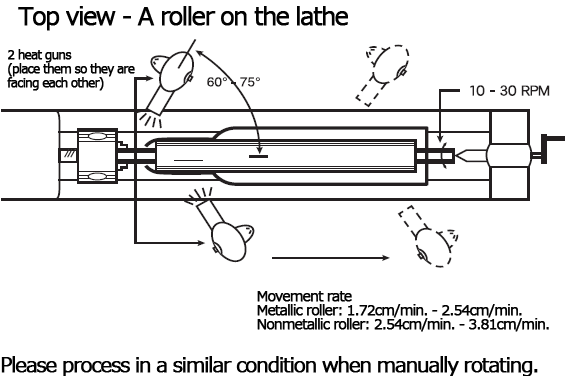

5. An oven (electric furnace) is most suited for shrinking processing due to reasons such as the entire tube being heated evenly as well as the low risk that heating will trigger the degradation or crack of the tube. If you will be using a heat gun, please refer to the plain view above that explains the correct processing method, and carry out the work in a way such that the entire tube will shrink evenly.

6. Please refer to the following table for the shrinking temperatures.

The heat shrinking temperatures listed on this website are only reference values. The actual heat shrinking temperatures will be affected by the specification and dimensions of the heat shrinking tubes, the processing methods and other conditions. Please contact our Technical Representative for details.

■ Precautions

■ FAQ

Q. What are the minimum lot sizes?

A. The minimum lot requirement depends on the size and the form of delivery. Please contact us for more information.

Q. The size we would like to order is not listed in the product list. Can the products be made in custom sizes?

A. We can make customized products. Our Product Specialist will help you with the setup. Please feel free to contact us for more information.