High Performance Sheet Gasket

Made of ceramic fiber (super heat resisting inorganic fiber) and excellent in flexibility and high temperature heat resistance, these are used as various types of sealing materials, as well as heat insulating material, shielding material and protective material. Since a small amount of organic fiber is included in the manufacturing process, some amount of smoke is generated at the initial stage of heating, while No.105SN cloth and No.112SN ribbon (liver) are smoking prevention treated. As core material of cloth and ribbon yarn, stainless wire is normally used, but others include glass fiber.

- VALQUA No.

- MF300 (Food)

- Product name

- BRIGHTHYPER

- Features1

- Gasket has more excellent chemical resistance than GF300 and SF300, and applicable for both acid and alkaline applications.

- Features2

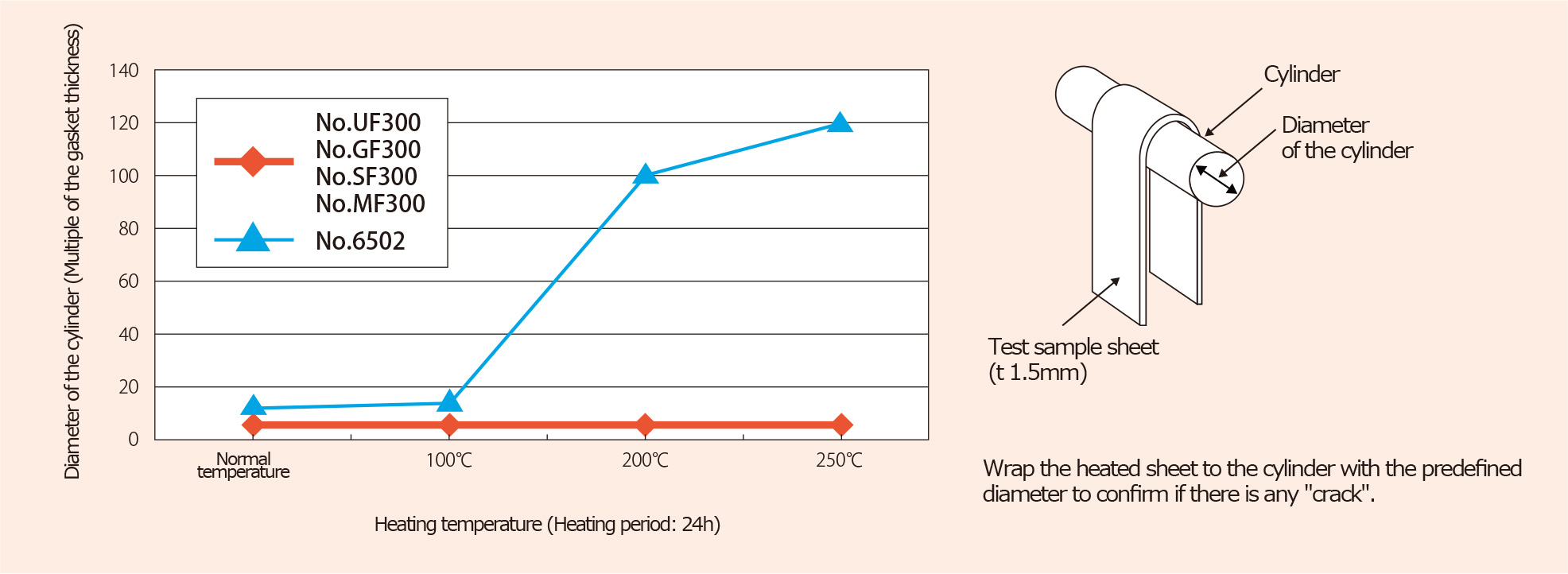

- This is solid white, and thus ideal for lines incompatible with contamination. It has long-term stablity under high temperature similar to other high performance sheet.

- Features3

- Ideal for lines requiring white color and high chemical resistance.

- Features4

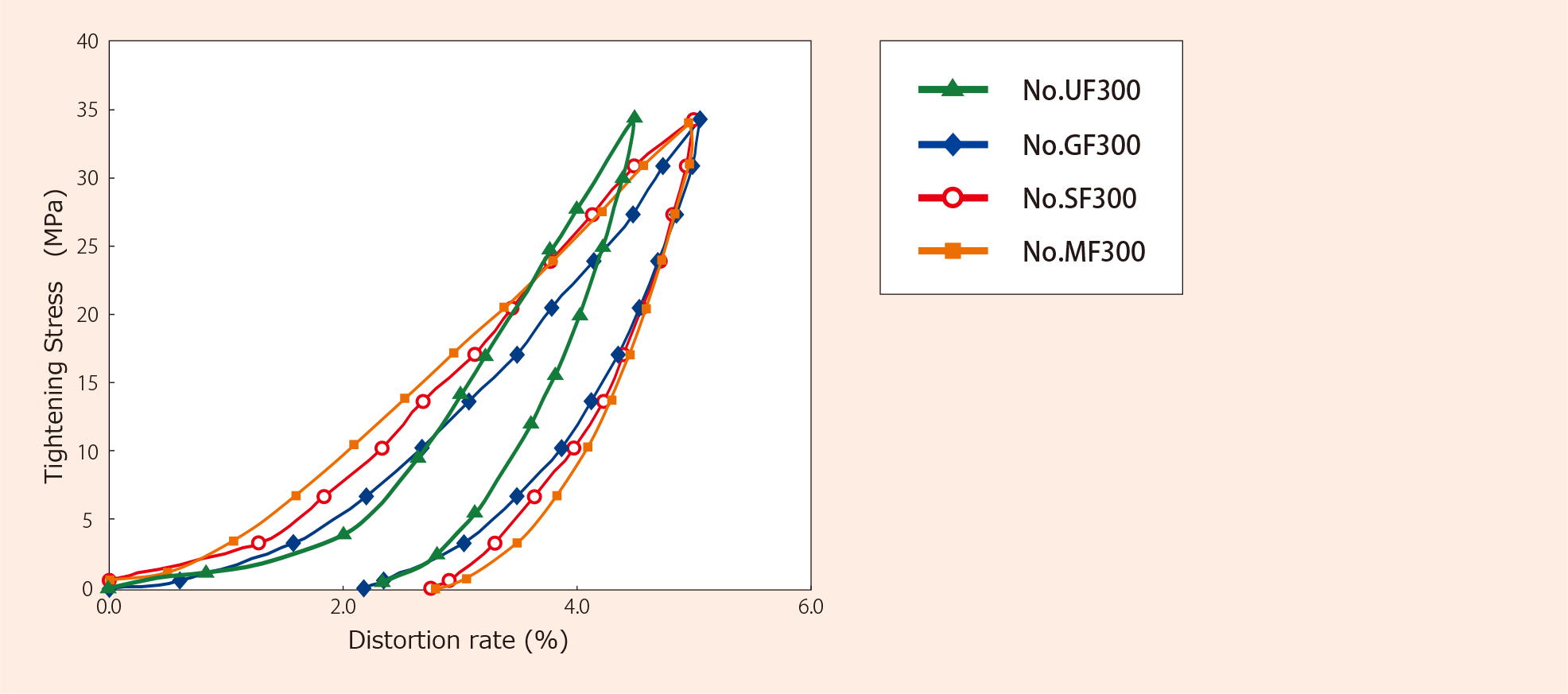

- This gasket possesses the same creep relaxation property as GF300. Please contact us if you are not satisfied with the reliability of other companies' white-colored products for long-term use under high temperatures.

- Features5

- These comply with the Food Sanitation Law.

Conforms to the Food Sanitation Act and standards for food and additives

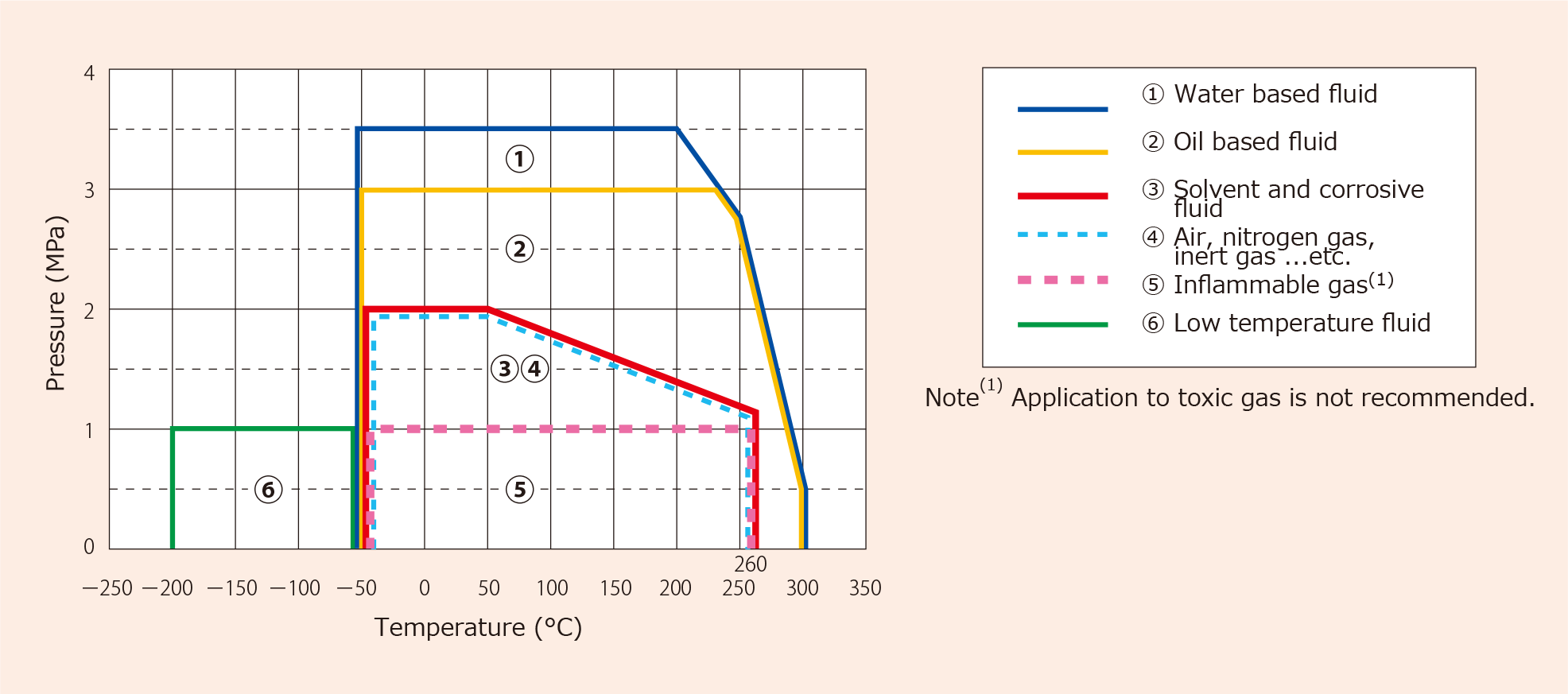

- Applicable fluid

- Water, sea water, hot water, steam,Crude oil, alcohol, animal and vegetable oils, thermal oil,General solvents, weak acid, weak alkali,Strong alkali, strong acid,Air, nitrogen, inert gas,Exhaust gas,Flammable gas,Oxygen,Cryogenic fluid,

- Inappropriate fluid

- Polymerizable monomer, Poisonous, Hydrofluoric acid

- Use

- Cover flanges, nozzles and other joints for pipe flanges, valve bonnets, towers and tanks, ovens, pressure vessels, and heat exchangers in factories, electric power plants, oil refineries, steel plants, and ships.

- Main component

- PTFE, Alumina

- Color / print

- White/Nothing