This product is used in lines that employ highly corrosive acid and alkali.

<Cases that deal with hydrochloric acid>

・ Recovery line of by-product hydrochloric acid

・ Lines that include unreacted hydrogen chloride in generated products

・ Lines that employ hydrochloric acid in catalysts or co-catalysts

・ Lines in which damp chlorine or chlorohydrin exist

・ Lines in which chlorine is suctioned in and turned into hydrochloride before proceeding to the next step

・ Lines in which hydrochloric acid is generated as a result of the hydrolysis of metal chloride

<Cases that deal with sulfuric acid>

・ Lines that concentrate sulfuric acid

・ Lines that employ sulfuric acid as a catalyst

<Line to deal with both of acid and alkali>

・ Lines in which sulfuric acid and sodium hydroxide flow alternately

<Cases that deal with fluorine>

・ Lines that contain high-temperature hydrogen fluoride

<By Industry Sector>

・ Lines of drug solutions for semiconductor (areas that have an aversion to contamination)

・ Lines such as of food and beverages

・ Manufacturing lines of clothing

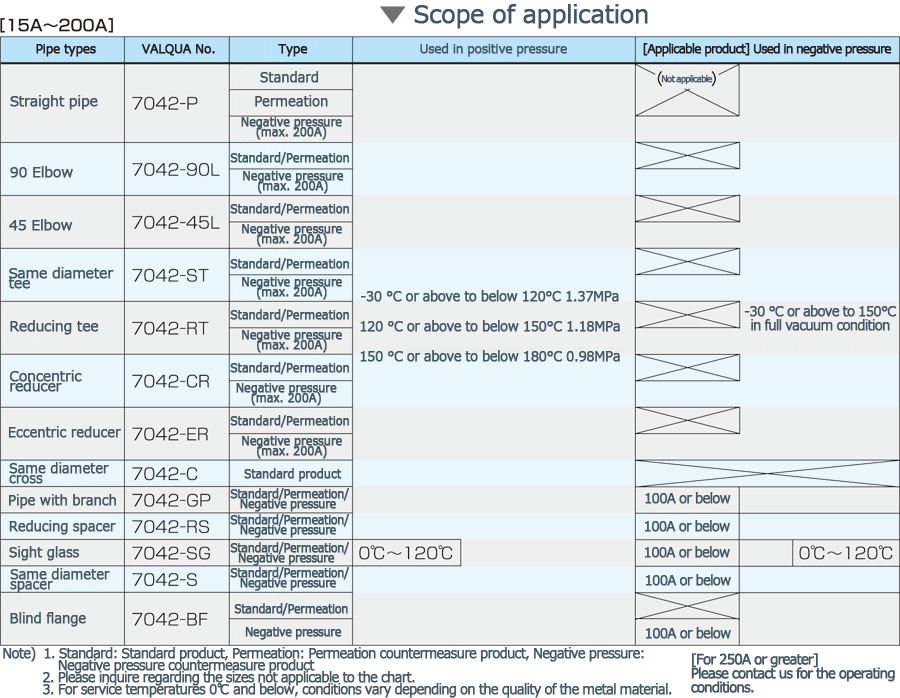

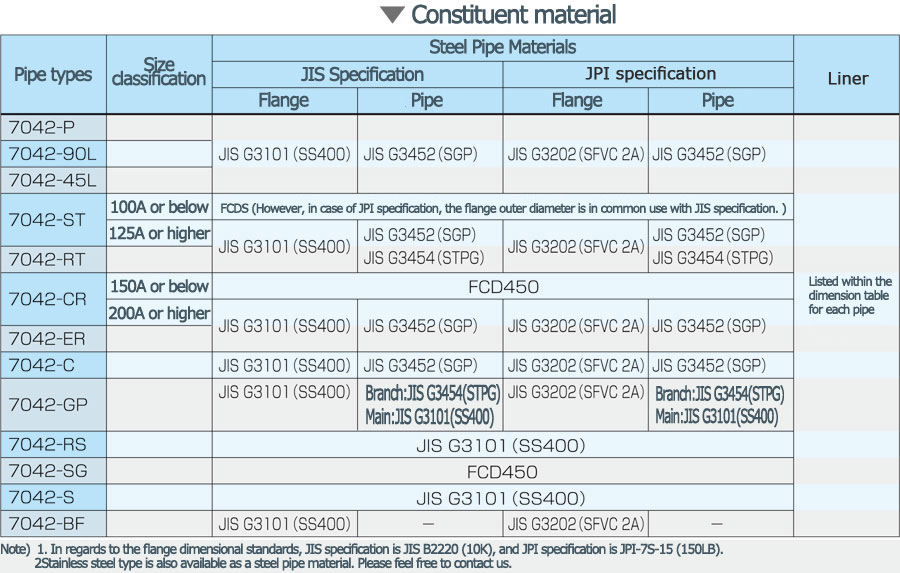

■ Scope of application

■ Constituent material

■ Product features

The main lining material of VALFLON ® Lining Steel Pipe is PTFE resin, and at VALQUA we have made efforts to implement densification by leveraging the characteristics of PTFE resin. As a result, we have reduced the amount of permeation and penetration of gas and drug solutions. (Densified PTFE material)

We have used PFA resin materials in some VALFLON® Lining Steel Pipe joint products, but when using PTFA resin, we have set the wall thickness of the lining material relatively thicker.

At VALQUA, we are carrying out the manufacture of products aiming to maximize “protection of steel pipe material from internal fluid,” which is the purpose of lining products.

■ Product lineup selection criteria

| Form |

Application classification |

Scope of application |

| Standard product |

Positive pressure area |

VALQUA standard liner |

| Permeation countermeasure product |

Penetration resistance area |

Permeation resistance liner |

| Negative pressure countermeasure product |

Negative pressure area |

Negative pressure countermeasure liner |

| Special specification countermeasure product |

Specialized area |

・Low temperature (40℃ or below)

・High temperature (0.8MPa or above)

・Please consult in advance if the three conditions for a highly penetrable drug solution (e.g. mixed drug solutions containing hydrochloric acid, fluorine, bromine, organic solvent, and additive agents, etc.) have occurred simultaneously. |

■ Product dimensions

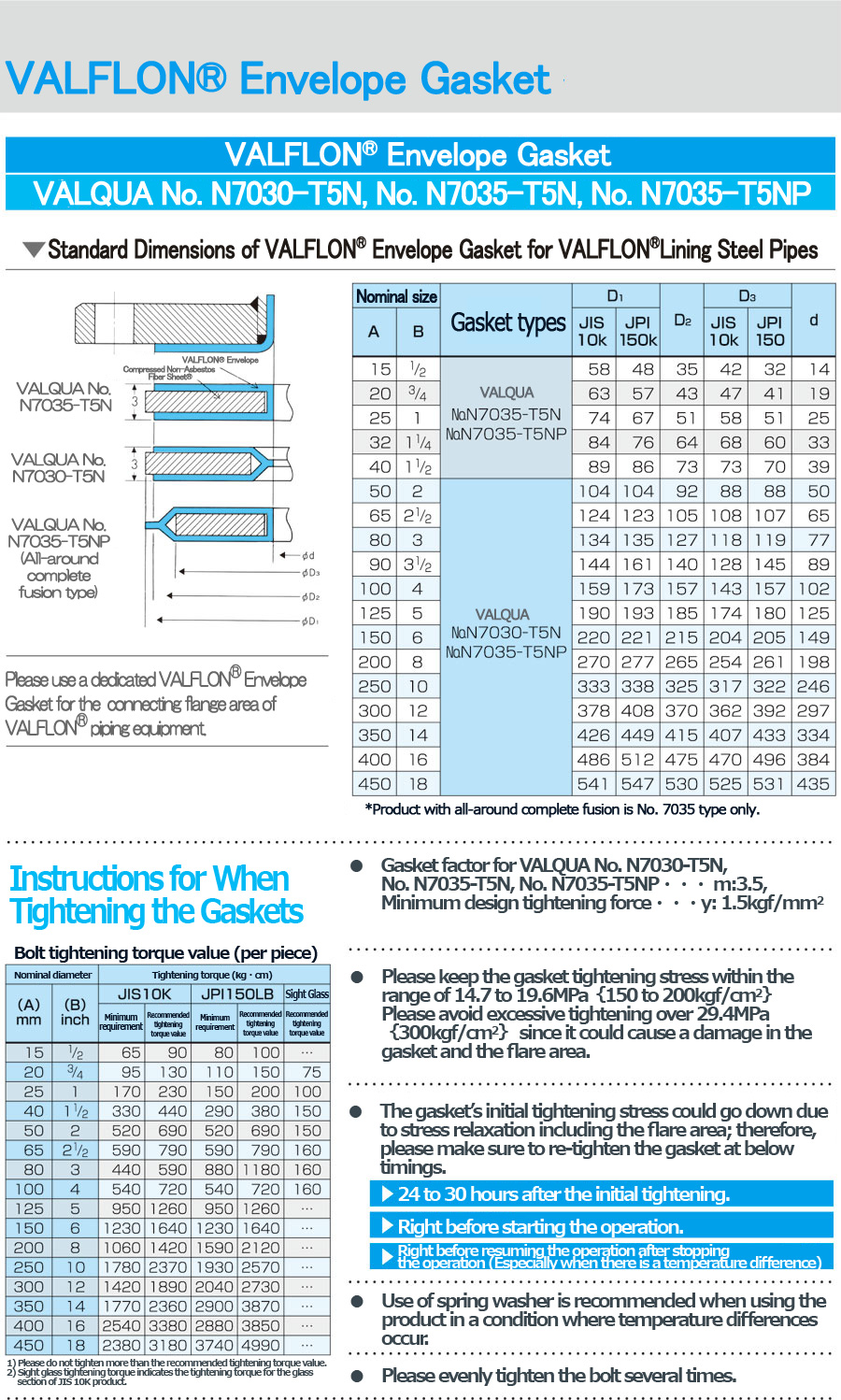

■ Gasket for lining steel pipe

■ Finished product inspection criteria

At VALQUA, we are carrying out the following inspections.

■ Plumbing and maintenance procedure

Work guidelines

(A) Not to remove the protective plate that protects the flare surface until immediately before the piping work.

(B) Always clean the VALFLON flare surface when piping.

(C) Absolutely prevent the uneven tightening of the flange.

(D) Follow these steps when tightening bolts: First, tighten the nut with your finger; next, sequentially tighten the bolt located at the cross to a certain extent; lastly, tighten the bolt until the required tightening torque value.

(E) Control the tightening torque at a tightening contact pressure between 9.8 and 19.6 MPa {100 to 200kgf/cm2}.

(F) Absolutely do not conduct ground wiring from the outer surface of the VALFLON lining pipe (triggering fire on a welding rode often performed during other welding work).

(G) Always re-check all bolts after 24 to 30 hours under normal temperature, or after one thermal load cycle, and retighten if insufficient torque is found by any chance.

(H) Always adjust the interface to the installing length when installing a bellows. After installation, return the nut of the limit bolt to the designated minimum interface, and fix it.

(I) Make sure not to block the vent hole when painting the pipe after assembly.

(J) Always use a spring washer together with a bolt.

(K) Always use a VALFLON Jacket Gasket (No.7030-N, No.7035-N) in the joint portion of the flange seal surface. Also, if the jacket gasket is removed after inspection, use a new jacket gasket.

Maintenance guidelines

(A) Inspection

・ Confirm that there is no weepage or leakage of the content solution on the flange tool surface.

・ Confirm that there is no leakage of the content solution from the vent hole (Φ3) processed in the hardware of the product.

・ Check the tightening torque of the bolt. By any chance, if a loosened bolt or torque-down is discovered, retighten the bolt according to the guidelines described above in (E).

(B) Response to abnormality

・ Retighten the bolt if a leakage of the content solution is discovered on the seal surface.

・ Consult us separately if you discover a leakage of the content solution from the vent hole, because there is an abnormality in the VALFLON liner and immediate countermeasures are necessary.

■ FAQ

Q. After assembling the pipes, there are leaks from the contact surface.

A. ①Please confirm that the bolt is tightened to the prescribed torque value. If it is loose, please re-tighten the bolt.

②Please make sure that there is no uneven tightening.