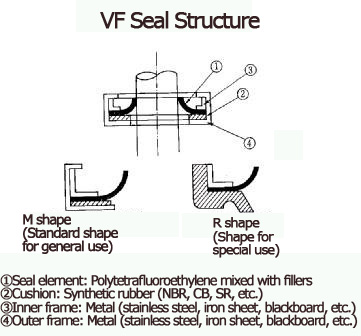

VALFLON V-Packing (No. 7631)

This is a lip-shaped packing in which PTFE resin is cut and processed. Compared to elastomer products, it has superior chemical resistance and low wear characteristics.

In addition, the temperature, pressure and wear resistance characteristics are improved by using materials containing fillers. There are three types of cross-section shapes, H, M and L, which are each classified according to their applications.

(A) Types and applications

| Types |

L-type |

M-type |

H-type |

|

|

|

| Applications |

Valve (control valve, etc.)

Agitator |

Plunger pump

High pressure valve |

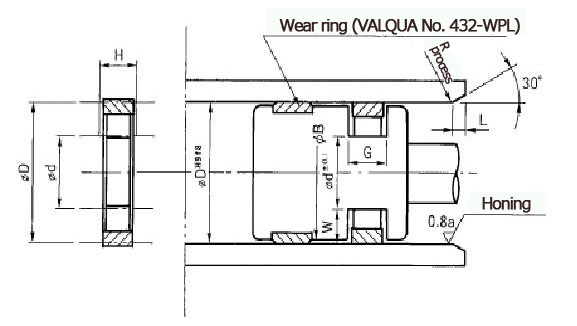

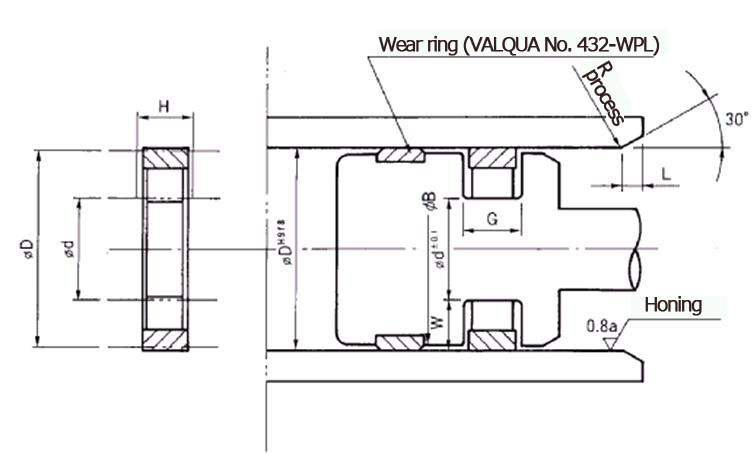

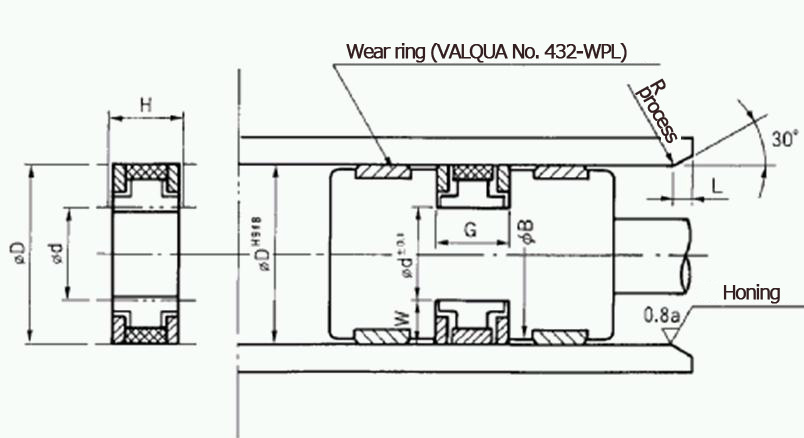

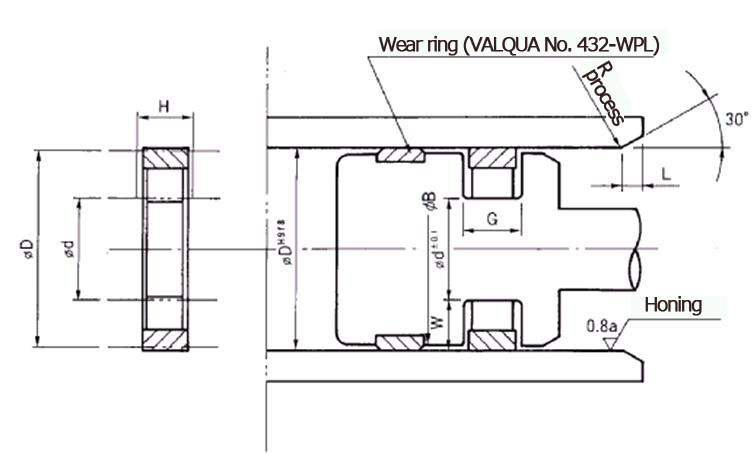

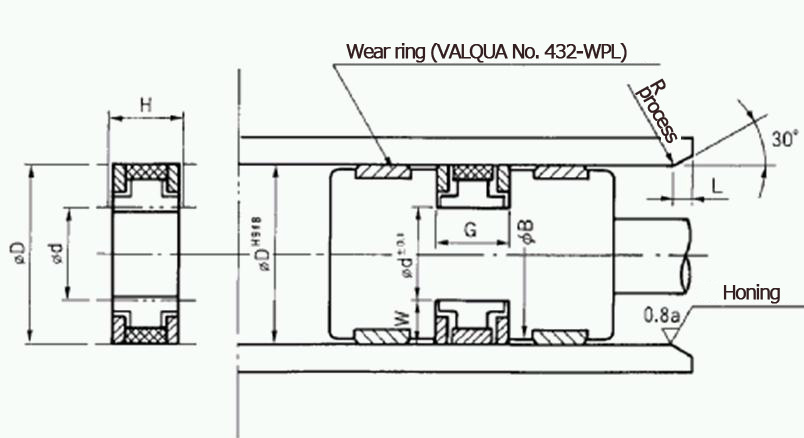

(B) Gland part design outline

(1) Operating pressure and number of packings

Having more than necessary rings that need to be mounted would actually increase the wear and reduce the seal effectiveness. The minimum standard mounting number is shown in the table below.

| Types |

Operating pressure range, MPa{kgf/cm2} |

Number of packings |

| L |

0~1.96MPa{0~20kgf/cm2} |

2~3 |

| M |

1.96~4.90MPa{20~50kgf/cm2} |

3 |

| 4.90~6.86MPa{50~70kgf/cm2} |

4 |

| H(1) |

6.86~14.70MPa{70~150kgf/cm2} |

5 |

| 14.70~29.40MPa{150~300kgf/cm2} |

6 |

Note: Used together with spacer rings

(2) Adapter ring

It would be permissible if the adapter ring were metallic, but the same quality should be used as much as possible.

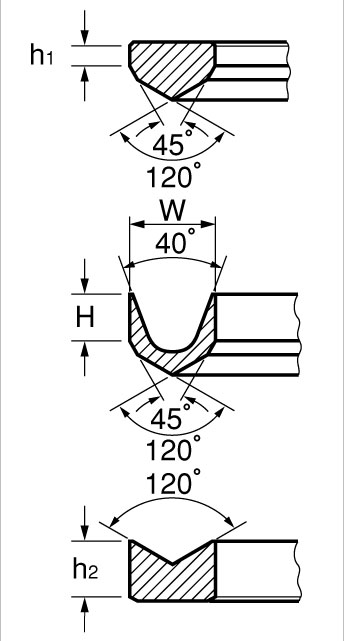

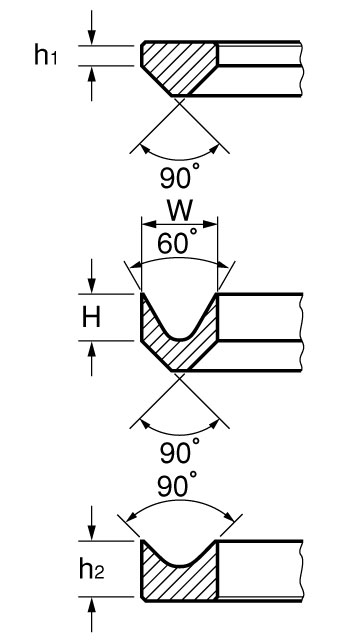

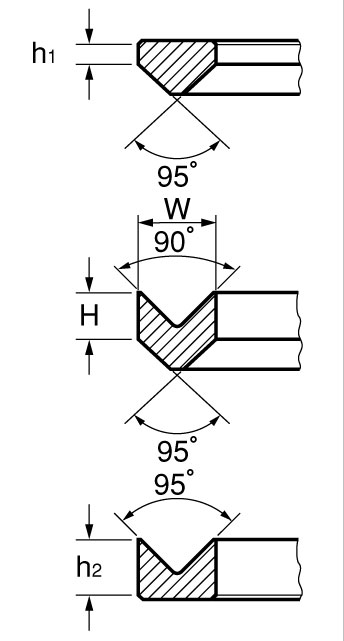

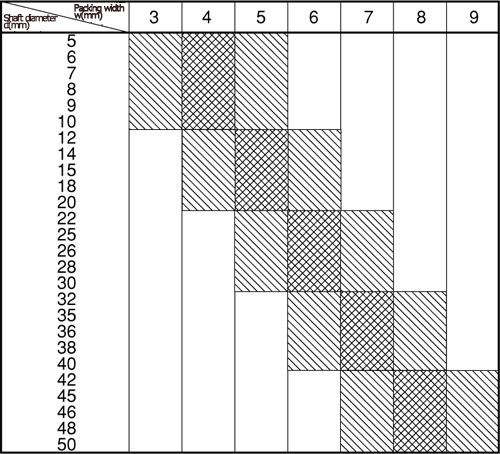

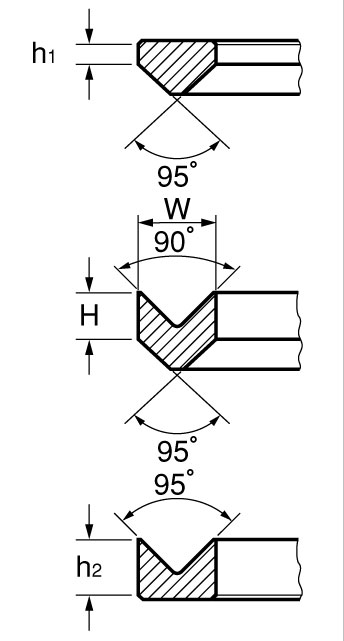

(3) Shaft diameter and packing width

W = Width of stuffing box

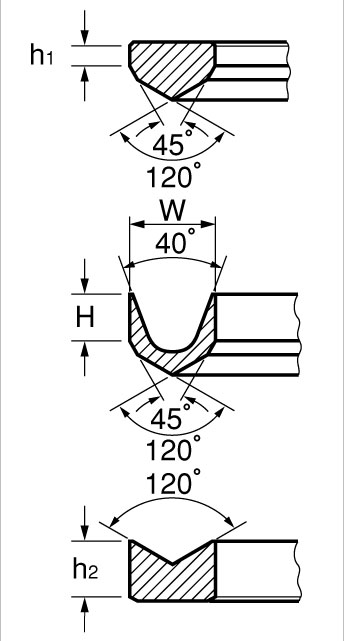

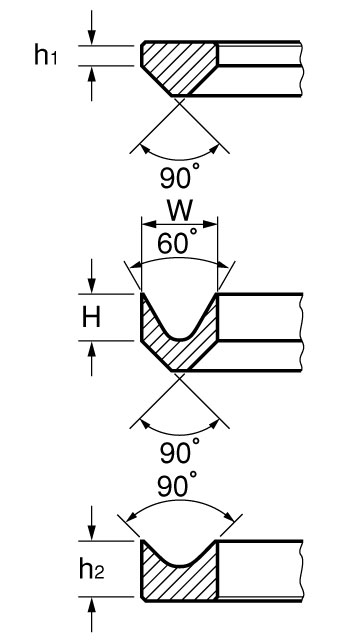

(4) Packing width and height

Packing width

W(mm) |

Packing height

H(mm) |

Adapter ring height

h1(mm) |

Adapter ring height

h2(mm) |

| 3 |

1.6 |

0.9 |

3 |

| 4 |

2.4 |

1.2 |

4 |

| 5 |

3 |

1.5 |

5 |

| 6 |

3.6 |

1.8 |

6 |

| 7 |

4.2 |

2.1 |

7 |

| 8 |

4.8 |

2.4 |

8 |

| 9 |

5.4 |

2.7 |

9 |

| 10 |

6 |

3 |

10 |

Note: Refer to items in (B) types and applications for marks H, h1 and h2.

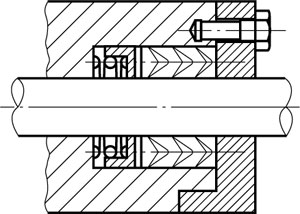

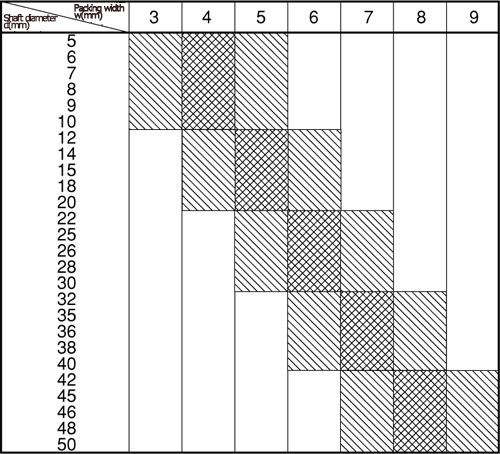

⑤Adjustment by spring

This gland packing easily shrinks when there is a significant temperature change. Therefore, in this case, it is effective to attach a spring and make an adjustment as shown below.

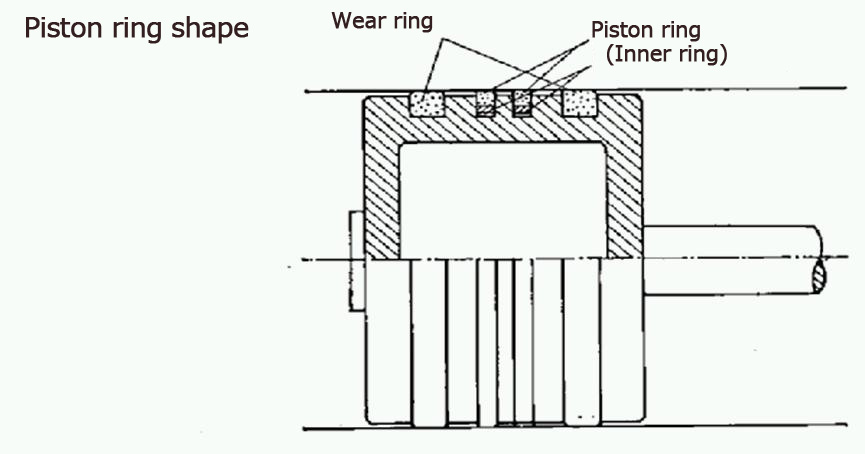

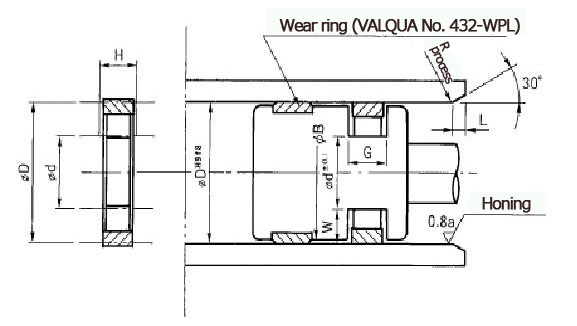

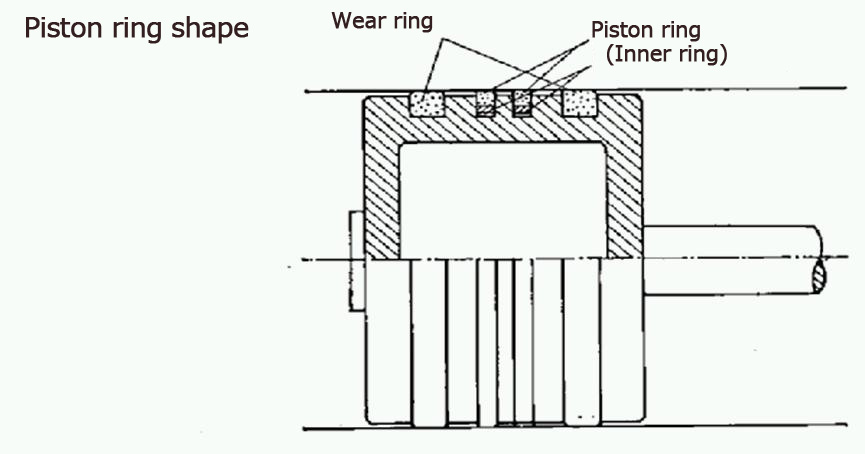

This is a piston ring in which a polytetrafluoroethylene (PTFE) is cut and processed into a designated shape.

Because a PTFE that has self-lubricating properties is used, it can be used in non-lubricated materials.

In addition, because there is little difference between the coefficient of static and dynamic friction, it is possible to begin operations smoothly.

This is a sealing material in which PTFE is cut and processed into an O-ring shape. It has excellent heat, chemical and solvent resistant characteristics, and it can be used as a sealing material for fixing. However, its compressive elasticity modulus differs from a rubber O-ring, so when using it, it will be necessary to adjust the groove dimensions and O-ring cross-section dimensions.

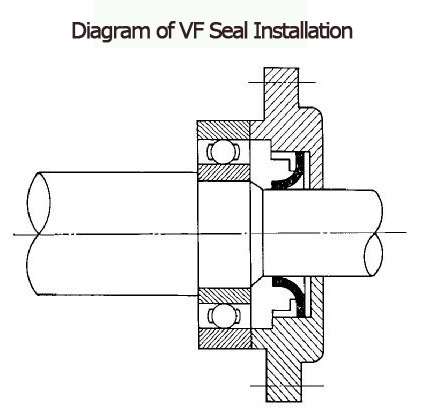

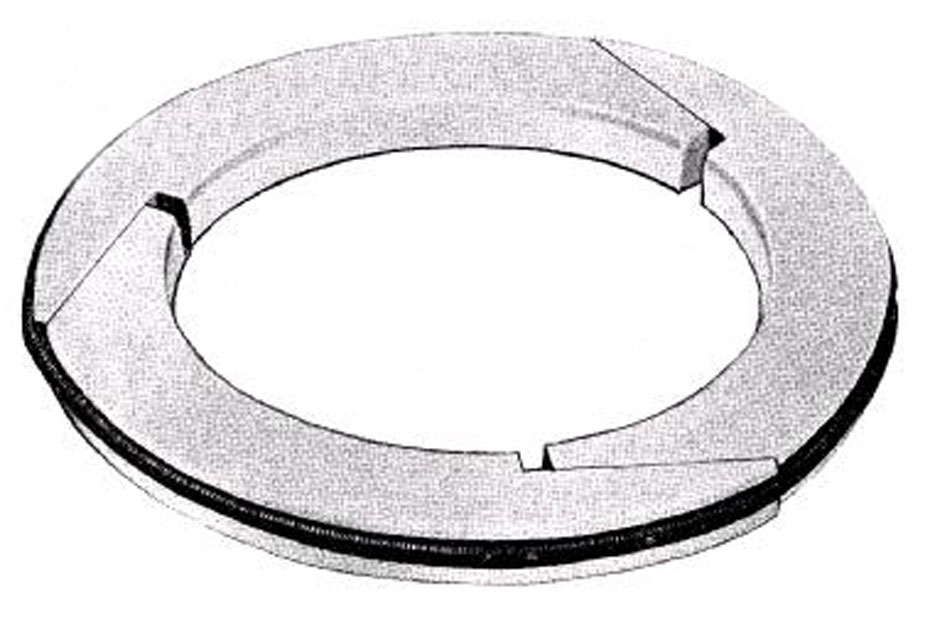

Slipper Seal (No. 7740 AP Series)

The slipper seal is a combination seal in which the sliding side is equipped with a ring made of fluororesin (PTFE) and the non-sliding side is equipped with an elastomer ring. This seal is frequently used as the outer diameter sealing material of reciprocating motion mainly in oil hydraulic equipment.

(1) Good wear resistance and durability.

(2) Less prone to stick slip even at low speed.

(3) In contrast to lip packings, one unit of it can seal bidirectional pressure.

(4) After mounting to an equipment, there is little sticking to the mating sliding surface even when left alone for many hours.

(5) There is little change in frictional resistance at high pressure and high speed.

(A) Quality of material

Standard quality of material: VALFLON ring..........VALFLON containing bronze powder

Back ring..............Nitrile rubber (NBR) Hs70

(B) Manufacturing ranges

Piston diameter: φ10 or above to φ1000

Note: A piston diameter lower than φ20 is used in split grooves. If the pressure will exceed 20.6 MPa {210 kgf/cm

2}, or if the diameter is φ300 or greater, a large cross-section is used.

(C) Standard dimensions

φ20 to φ250 is standardized based on the dimensional specification of the JIS oil hydraulic cylinder.

There is mainly the reciprocating motion actuator of an oil hydraulic cylinder, rotary and swivel joint as well as other various equipment, and in terms of the market for these equipment, there are construction machinery, oil hydraulic robots, machine tools, presses, injection molding machines, heavy machinery, iron and steel, automobiles, airplanes, etc.

This is a piston ring in which a polytetrafluoroethylene (PTFE) is cut and processed into a designated shape.

This is a piston ring in which a polytetrafluoroethylene (PTFE) is cut and processed into a designated shape.

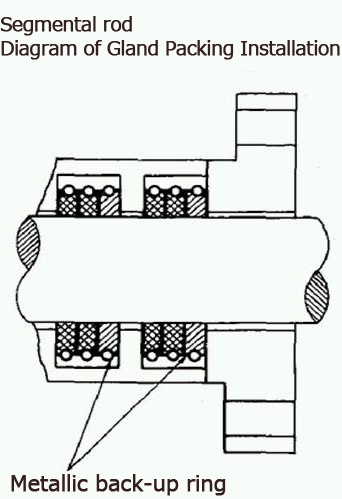

The split type rod packing is a product in which a PTFE ring containing filler, which has excellent wear resistance properties, is cut and processed into a split type shape. A metallic back-up ring is mounted before use.

The split type rod packing is a product in which a PTFE ring containing filler, which has excellent wear resistance properties, is cut and processed into a split type shape. A metallic back-up ring is mounted before use. This is a sealing material in which PTFE is cut and processed into an O-ring shape. It has excellent heat, chemical and solvent resistant characteristics, and it can be used as a sealing material for fixing. However, its compressive elasticity modulus differs from a rubber O-ring, so when using it, it will be necessary to adjust the groove dimensions and O-ring cross-section dimensions.

This is a sealing material in which PTFE is cut and processed into an O-ring shape. It has excellent heat, chemical and solvent resistant characteristics, and it can be used as a sealing material for fixing. However, its compressive elasticity modulus differs from a rubber O-ring, so when using it, it will be necessary to adjust the groove dimensions and O-ring cross-section dimensions.