PTFE Substrate (For HF Wave/MM Wave)

“PTFE substrates are used as high-frequency peripheral equipment parts such as antennas in high-frequency areas by their excellent dielectric characteristics and coefficient of water absorption.

In recent years, with the diversification of information in the telecommunications field, higher frequencies have been implemented in the radio waves used, and it has also become necessary for the antennas and circuit components used in information communication to adapt to higher frequencies.”

■ Product lineup

■ PTFE + Glass cloth

| Product No. | Dielectric constant | Dielectric tangent |

|---|---|---|

| TLY-5A | 2.17(a) | 0.0009(a) |

| TLY-5 | 2.20(a) | 0.0009(a) |

| TLY-3 | 2.33(a) | 0.0012(a) |

| TLX-0 | 2.45(a) | 0.0019(a) |

| TLX-9 | 2.50(a) | 0.0019(a) |

| TLX-8 | 2.55(a) | 0.0019(a) |

| TLX-7 | 2.60(a) | 0.0019(a) |

| TLX-6 | 2.65(a) | 0.0019(a) |

| TLC-27 | 2.75(a) | 0.0030(a) |

| TLC-30 | 3.00(a) | 0.0030(a) |

| TLC-32 | 3.20(a) | 0.0030(a) |

| TLE-95 | 2.95(a) | 0.0028(a) |

The values of the dielectric constant and dielectric tangent are measured by the following measurement methods.

(a) Measurement by IPC-TM-650 method 2.5.5.5 (10GHz)

(b) Measurement by IPC-TM-650 method 2.5.5.5.1 (1.9GHz)

(c) Measurement by IPC-TM-650 method 2.5.5.5.1 (10GHz)

(d) Measurement by IPC-TM-650 method 2.5.5.6

(e) Measurement by ASTM D3380 (10GHz)

(f) The dielectric constant varies depending on the thickness.

■ PTFE + Ceramic + Glass Cloth

| Product No. | Dielectric constant | Dielectric tangent |

|---|---|---|

| RF-30 | 3.00(b) | 0.0014(b) |

| RF-35 | 3.50(b) | 0.0018(b) |

| RF-35A2 | 3.50(c) | 0.0015(c) |

| TLF-34 | 3.40(b) | 0.0020(c) |

| TLF-35 | 3.50(b) | 0.0020(c) |

| TRF-41 | 4.10(c) | 0.0035(c) |

| TRF-43 | 4.30(c) | 0.0035(c) |

| TRF-45 | 4.50(c) | 0.0035(c) |

| RF-60A | 6.15(d) | 0.0038(c) |

| CER-10 | 9.0-10.7(d)(f) | 0.0035(c) |

The values of the dielectric constant and dielectric tangent are measured by the following measurement methods.

(a) Measurement by IPC-TM-650 method 2.5.5.5 (10GHz)

(b) Measurement by IPC-TM-650 method 2.5.5.5.1 (1.9GHz)

(c) Measurement by IPC-TM-650 method 2.5.5.5.1 (10GHz)

(d) Measurement by IPC-TM-650 method 2.5.5.6

(e) Measurement by ASTM D3380 (10GHz)

(f) The dielectric constant varies depending on the thickness.

■ Bonding Film

| Product No. | Material composition | Dielectric constant | Dielectric tangent |

|---|---|---|---|

| HT1.5 | Bonding Film | 2.35(e) | 0.0025(e) |

| fastRise™ | Prepreg/Thermosetting resin | 2.70(c) | 0.0014(c) |

| TPG-30 | Prepreg/Thermosetting resin | 3.00(c) | 0.0038(c) |

| TPG-35 | Prepreg/Thermosetting resin | 3.50(c) | 0.0050(c) |

The values of the dielectric constant and dielectric tangent are measured by the following measurement methods.

(a) Measurement by IPC-TM-650 method 2.5.5.5 (10GHz)

(b) Measurement by IPC-TM-650 method 2.5.5.5.1 (1.9GHz)

(c) Measurement by IPC-TM-650 method 2.5.5.5.1 (10GHz)

(d) Measurement by IPC-TM-650 method 2.5.5.6

(e) Measurement by ASTM D3380 (10GHz)

(f) The dielectric constant varies depending on the thickness.

All products other than HT1.5, fastRise™ are approved under UL standards (94V-O).

■ Special product

| Product No. | Dielectric constant | Dielectric tangent | Features |

|---|---|---|---|

| TacLamPlus™ | 2.10(c) | 0.0004(c) | Glass cloth-less metal-based substrate for low-loss circuit design Via forming by laser processing is available |

The values of the dielectric constant and dielectric tangent are measured by the following measurement methods.

(a) Measurement by IPC-TM-650 method 2.5.5.5 (10GHz)

(b) Measurement by IPC-TM-650 method 2.5.5.5.1 (1.9GHz)

(c) Measurement by IPC-TM-650 method 2.5.5.5.1 (10GHz)

(d) Measurement by IPC-TM-650 method 2.5.5.6

(e) Measurement by ASTM D3380 (10GHz)

(f) The dielectric constant varies depending on the thickness.

■ New product

| Product No. | Dielectric constant | Dielectric tangent | Features |

|---|---|---|---|

| RF-35TC | 3.50(c) | 0.0011(c) | High thermal conductivity – Dimensional stability – Low dielectric constant |

| TSM-DS3 | 3.00(a) | 0.0011(a) | Low linear expansion coefficient – For multi-layer substrates – Dimensional stability – Thermal conductivity |

| RF-301 | 2.97(b) | 0.0012(b) | Antenna grade – Low-cost type |

The values of the dielectric constant and dielectric tangent are measured by the following measurement methods.

(a) Measurement by IPC-TM-650 method 2.5.5.5 (10GHz)

(b) Measurement by IPC-TM-650 method 2.5.5.5.1 (1.9GHz)

(c) Measurement by IPC-TM-650 method 2.5.5.5.1 (10GHz)

(d) Measurement by IPC-TM-650 method 2.5.5.6

(e) Measurement by ASTM D3380 (10GHz)

(f) The dielectric constant varies depending on the thickness.

■ Product thickness

| Product No. | Thickness | |||

|---|---|---|---|---|

| Dielectric thickness | Tolerance | Dielectric thickness | Tolerance | |

| [mm]* | [mm]* | [inch] | [inch] | |

| TLY-3,5,5A | 0.127 | ±0.020 | 0.0050 | ±0.0008 |

| 0.191 | ±0.025 | 0.0075 | ±0.0010 | |

| 0.254 | ±0.025 | 0.0100 | ±0.0010 | |

| 0.381 | ±0.040 | 0.0150 | ±0.0016 | |

| 0.508 | ±0.050 | 0.0200 | ±0.0020 | |

| 0.635 | ±0.050 | 0.0250 | ±0.0020 | |

| 0.762 | ±0.050 | 0.0300 | ±0.0020 | |

| 0.787 | ±0.050 | 0.0310 | ±0.0020 | |

| 1.016 | ±0.050 | 0.0400 | ±0.0020 | |

| 1.143 | ±0.050 | 0.0450 | ±0.0020 | |

| 1.575 | ±0.050 | 0.0620 | ±0.0020 | |

| 2.032 | ±0.075 | 0.0800 | ±0.0030 | |

| 2.362 | ±0.075 | 0.0930 | ±0.0030 | |

| 2.540 | ±0.075 | 0.1000 | ±0.0030 | |

| 3.175 | ±0.090 | 0.1250 | ±0.0036 | |

| TLX-0,9,8,7,6 | 0.089 | ±0.015 | 0.0035 | ±0.0006 |

| 0.127 | ±0.020 | 0.0050 | ±0.0008 | |

| 0.216 | ±0.025 | 0.0085 | ±0.0010 | |

| 0.254 | ±0.025 | 0.0100 | ±0.0010 | |

| 0.381 | ±0.040 | 0.0150 | ±0.0016 | |

| 0.508 | ±0.050 | 0.0200 | ±0.0020 | |

| 0.787 | ±0.050 | 0.0310 | ±0.0020 | |

| 1.016 | ±0.050 | 0.0400 | ±0.0020 | |

| 1.143 | ±0.050 | 0.0450 | ±0.0020 | |

| 1.575 | ±0.050 | 0.0620 | ±0.0020 | |

| 1.905 | ±0.075 | 0.0750 | ±0.0030 | |

| 2.007 | ±0.075 | 0.0790 | ±0.0030 | |

| 2.362 | ±0.075 | 0.0930 | ±0.0030 | |

| 3.048 | ±0.090 | 0.1200 | ±0.0036 | |

| 3.175 | ±0.090 | 0.1250 | ±0.0036 | |

| TLC-27,30,32 | 0.368 | ±0.040 | 0.0145 | ±0.0016 |

| 0.508 | ±0.050 | 0.0200 | ±0.0020 | |

| 0.787 | ±0.050 | 0.0310 | ±0.0020 | |

| 1.143 | ±0.050 | 0.0450 | ±0.0020 | |

| 1.575 | ±0.050 | 0.0620 | ±0.0020 | |

| 2.362 | ±0.075 | 0.0930 | ±0.0030 | |

| TLE-95 | 0.089 | ±0.015 | 0.0035 | ±0.0006 |

| 0.132 | ±0.020 | 0.0052 | ±0.0008 | |

| 0.254 | ±0.025 | 0.0100 | ±0.0010 | |

| 0.508 | ±0.050 | 0.0200 | ±0.0020 | |

| TSM-DS3 | 0.127 | ±0.020 | 0.0050 | ±0.0008 |

| 0.254 | ±0.025 | 0.0100 | ±0.0010 | |

| 0.381 | ±0.040 | 0.0150 | ±0.0016 | |

| 0.508 | ±0.050 | 0.0200 | ±0.0020 | |

| 0.762 | ±0.050 | 0.0300 | ±0.0020 | |

| 1.016 | ±0.050 | 0.0400 | ±0.0020 | |

| 1.270 | ±0.050 | 0.0500 | ±0.0020 | |

| 1.524 | ±0.050 | 0.0600 | ±0.0020 | |

| 1.778 | ±0.075 | 0.0700 | ±0.0030 | |

| 2.286 | ±0.075 | 0.0900 | ±0.0030 | |

| RF-30 | 0.254 | ±0.025 | 0.0100 | ±0.0010 |

| 0.508 | ±0.050 | 0.0200 | ±0.0020 | |

| 0.762 | ±0.050 | 0.0300 | ±0.0020 | |

| 1.524 | ±0.050 | 0.0600 | ±0.0020 | |

| RF-35TC | 0.127 | ±0.013 | 0.0050 | ±0.0005 |

| 0.254 | ±0.025 | 0.0100 | ±0.0010 | |

| 0.508 | ±0.050 | 0.0200 | ±0.0020 | |

| 0.762 | ±0.050 | 0.0300 | ±0.0020 | |

| 1.524 | ±0.050 | 0.0600 | ±0.0020 | |

| Product No. | Thickness | |||

|---|---|---|---|---|

| Dielectric thickness | Tolerance | Dielectric thickness | Tolerance | |

| [mm]* | [mm]* | [inch] | [inch] | |

| RF-35 | 0.254 | ±0.025 | 0.0100 | ±0.0010 |

| 0.508 | ±0.050 | 0.0200 | ±0.0020 | |

| 0.762 | ±0.050 | 0.0300 | ±0.0020 | |

| 1.016 | ±0.050 | 0.0400 | ±0.0020 | |

| 1.270 | ±0.050 | 0.0500 | ±0.0020 | |

| 1.524 | ±0.050 | 0.0600 | ±0.0020 | |

| RF-35A2 | 0.127 | ±0.020 | 0.0050 | ±0.0008 |

| 0.254 | ±0.025 | 0.0100 | ±0.0010 | |

| 0.508 | ±0.050 | 0.0200 | ±0.0020 | |

| 0.762 | ±0.050 | 0.0300 | ±0.0020 | |

| 1.016 | ±0.050 | 0.0400 | ±0.0020 | |

| 1.524 | ±0.050 | 0.0600 | ±0.0020 | |

| TLF-34,35 | 0.254 | ±0.025 | 0.0100 | ±0.0010 |

| 0.508 | ±0.050 | 0.0200 | ±0.0020 | |

| 0.762 | ±0.050 | 0.0300 | ±0.0020 | |

| 1.016 | ±0.050 | 0.0400 | ±0.0020 | |

| 1.524 | ±0.050 | 0.0600 | ±0.0020 | |

| TRF-41,43,45 | 0.203 | ±0.025 | 0.0080 | ±0.0010 |

| 0.406 | ±0.040 | 0.0160 | ±0.0016 | |

| 0.610 | ±0.050 | 0.0240 | ±0.0020 | |

| 0.813 | ±0.050 | 0.0320 | ±0.0020 | |

| 1.016 | ±0.050 | 0.0400 | ±0.0020 | |

| 1.626 | ±0.050 | 0.0640 | ±0.0020 | |

| 2.540 | ±0.075 | 0.1000 | ±0.0030 | |

| 3.048 | ±0.090 | 0.1200 | ±0.0036 | |

| 5.994 | ±0.100 | 0.2360 | ±0.0040 | |

| RF-60A | 0.254 | ±0.025 | 0.0100 | ±0.0010 |

| 0.381 | ±0.040 | 0.0150 | ±0.0016 | |

| 0.635 | ±0.050 | 0.0250 | ±0.0020 | |

| 0.787 | ±0.050 | 0.0310 | ±0.0020 | |

| 1.016 | ±0.050 | 0.0400 | ±0.0020 | |

| 1.270 | ±0.050 | 0.0500 | ±0.0020 | |

| 1.524 | ±0.050 | 0.0600 | ±0.0020 | |

| 1.905 | ±0.075 | 0.0750 | ±0.0030 | |

| 2.286 | ±0.075 | 0.0900 | ±0.0030 | |

| 3.175 | ±0.090 | 0.1250 | ±0.0036 | |

| CER-10 | 0.102 | ±0.015 | 0.0040 | ±0.0006 |

| 0.203 | ±0.025 | 0.0080 | ±0.0010 | |

| 0.279 | ±0.025 | 0.0110 | ±0.0010 | |

| 0.381 | ±0.040 | 0.0150 | ±0.0016 | |

| 0.508 | ±0.050 | 0.0200 | ±0.0020 | |

| 0.635 | ±0.050 | 0.0250 | ±0.0020 | |

| 0.762 | ±0.050 | 0.0300 | ±0.0020 | |

| 1.016 | ±0.050 | 0.0400 | ±0.0020 | |

| 1.194 | ±0.050 | 0.0470 | ±0.0020 | |

| 1.270 | ±0.050 | 0.0500 | ±0.0020 | |

| 1.575 | ±0.050 | 0.0620 | ±0.0020 | |

| 1.905 | ±0.075 | 0.0750 | ±0.0030 | |

| 2.540 | ±0.075 | 0.1000 | ±0.0030 | |

| 3.175 | ±0.090 | 0.1250 | ±0.0036 | |

| RF-301 | 0.762 | ±0.050 | 0.0300 | ±0.0020 |

| 1.524 | ±0.050 | 0.0600 | ±0.0020 | |

* The values of the millimeter calculations [mm] have been converted from the inch calculations [in].

Please contact us if you desire a different thickness.

■ Copper foil lineup

| Copper foil symbol | Surface roughness RMS (treated surface) | Surface roughness RMS (untreated surface) | Type | Thickness | |||

|---|---|---|---|---|---|---|---|

| [μ m]* | [μ in] | [μ m]* | [μ in] | [μ m]* | [mil] | ||

| RH | 0.4 | 16 | 0.2 | 7 | Rolling copper foil 1/2oz | 17.5 | 0.7 |

| R1 | 0.3 | 11 | 0.2 | 7 | Rolling copper foil 1oz | 35.0 | 1.4 |

| CLH | 0.3 | 13 | 0.5 | 20 | Reverse treatment method electrolytic copper foil 1/2oz | 17.5 | 0.7 |

| CL1 | 0.3 | 13 | 0.6 | 25 | Reverse treatment method electrolytic copper foil 1oz | 35.0 | 1.4 |

| CH | 0.7 | 27 | 0.3 | 11 | Low profile electrolytic copper foil 1/2oz | 17.5 | 0.7 |

| C1 | 0.6 | 25 | 0.3 | 11 | Low profile electrolytic copper foil 1oz | 35.0 | 1.4 |

| C2 | 2.0 | 77 | 0.2 | 8 | Electrolytic copper foil 2oz | 70.0 | 2.8 |

* The values of the micro calculations [μm] and millimeter calculations [mm] have been converted from the inch calculations [in].

Please contact us if you desire a different copper foil type, thickness or other substrate size.

For the rolling copper foil (RH/R1), we do not offer 914mmx1220mm.

■ Standard size

| Specified length size | Cut size | ||

|---|---|---|---|

| [mm]* | [inch] | [mm]* | [inch] |

| 914×1220 | 36×48 | 304×457 | 12×18 |

| 406×457 | 16×18 | ||

| 457×610 | 18×24 | ||

| 406×914 | 16×36 | ||

| 610×914 | 24×36 | ||

Please contact us if you desire a different substrate size.

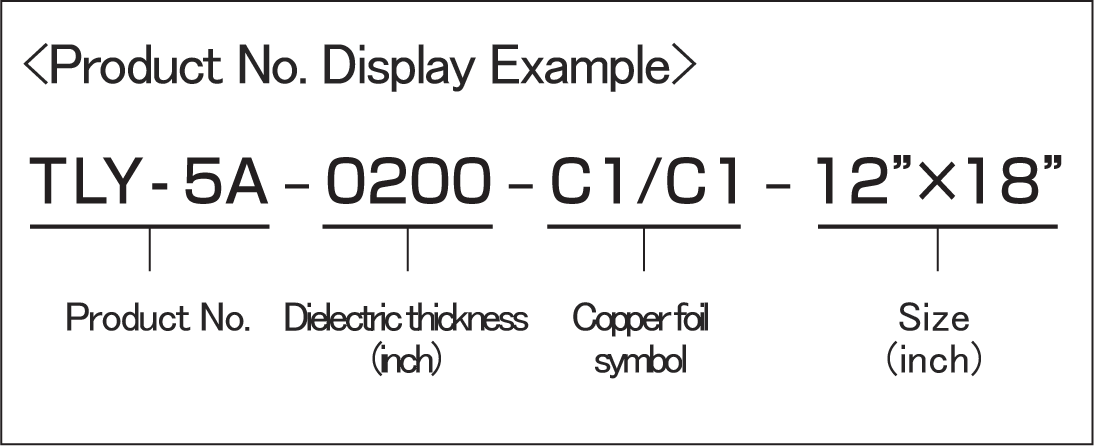

■ Display example of Product No.

■ Precautions

〈Precautions for safe use〉

・ Please do not use the product for purposes and methods other than those described in the catalog or the like.

・ Please do not use the product for applications involving transplants to the human body as well as contact with body fluid or body tissue.

・ Thoroughly ventilate or air places that are heated in excess of 200℃, and make sure not to inhale cracked gas.

・ Please do not use the product at a temperature exceeding 260℃ except during multilayered processes and solder joining.

・ When disposing the product, follow the “Waste Management and Public Cleaning Law” and discard them as industrial waste. Do not incinerate the product.

・ Please review the material safety data sheet (MSDS) for precautions regarding occupational safety and health.

*TacLamplus and fastRise are product names of Taconic.

The characteristic values of products may vary depending on factors such as substrate thickness, application, processing method or measuring environment, so please check on your own if the product is appropriate for the application by thoroughly conducting tests or the like.

The specifications of products are subject to change without prior notice.

Please note in advance that the content of this catalog may be revised without prior notice due to reasons including but not limited to the functional improvement of products.

In addition, the numerical values listed in this catalog are only for reference. We do not guarantee commensurate functionality under all conditions.

VALQUA has exclusive handling of Taconic products.

We prohibit the reproduction or reprinting of the content in this catalog without permission.

■ FAQ

Q. What are the minimum lot sizes?

A. In standard cut size (inches), they are the following: 12 x 18 – 8 sheets, 16 x 8 – 6 sheets, 18 x 24 – 4 sheets, 16 x 36 – 3 sheets

Special cut sizes are possible. Please contact our Product Representative.

Q. Do you have prepreg for HF wave?

A. We offer the Fastrise product. Please contact our Product Representative for more information.

Q. What is the standard copper foil?

A. The standard copper foils are the low profile electrolytic copper foil and reverse treatment method electrolytic copper foil.

■ Catalog and Leaflet

■ Contact Us

VALQUA, LTD.

■ Head Office ThinkPark Tower 24F, 2-1-1, Osaki, Shinagawa-ku, Tokyo, 141-6024, Japan

https://www.valqua.co.jp

■ Functional Resin Business Division

● Sales Dept. (Tokyo) Phone: +81-3-5434-7389 Fax: +81-3-5436-0578

● Sales Dept. (Osaka) Phone: +81-6-6443-5275 Fax: +81-6-6443-5276