■ Notes to be observed in design and usage ■

▼Notes to be observed in design

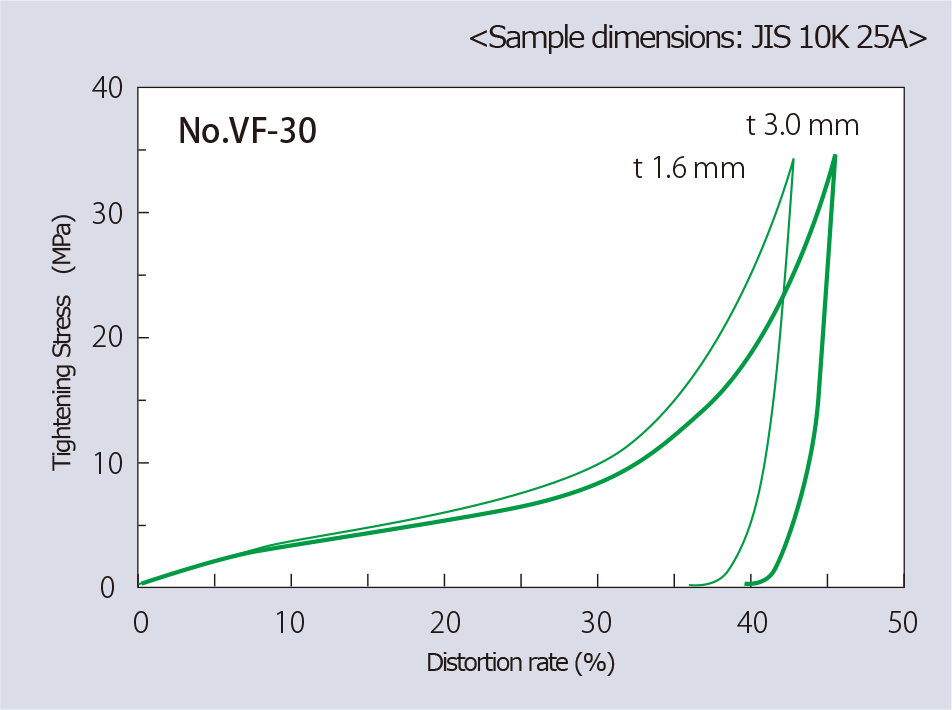

・Determine the number and size of bolts and gasket dimensions to provide gaskets with sufficient tightening stress, and also check the flange construction and bolt arrangement to ensure uniform distribution of tightening stress.

・In case of considering as an alternative for Compressed Fiber Sheet, be careful about the pipe length, as the compressibility will be larger than the Compressed Fiber Sheet.

・Consideration shall be given in design to prevent application of excessive thermal stress or repetitive bending stress on the joints.

・Piping design shall not allow accumulation of drain or scale at the flange sections.

▼Notes to be observed before installation

・When installing gas seals, refer to the following"Countermeasures against permeation leakage".

・Install the gaskets in a clean environment so as to prevent entry of foreign matters between the gaskets and the flanges.

・Flange bolts No.1 to 8 as shown on the figure shall be gradually tightened in this order at a time, and repeat this process in four to five steps, so as to finally ensure uniform tightening.

・When tightening, pay attention to prevent the occurrence of crush. Especially when using gaskets of 150 Lb, 1B or smaller, or those of smaller gasket width, care shall be given as gasket stress is likely to be excessive.

・At the time of load up or restarting, check for any loose bolts.

・f retightening of gaskets that have once experienced leakage failed in preventing leakage, replace them with new ones.

・Since allowance of gasket stress is low, please pay attention to prevent crush in case of small diameter gaskets.

▼Countermeasures against permeation leakage

Since permeation leakage is prone to occur in VALQUAFOIL gasket, the following points shall be observed for gas seals:

1.Apply gasket paste on the cut surface of the gasket inner diameter side. Application of gasket paste on the contact surface between the gasket and the flange is likely to cause crush, so that careful attention is required in tightening, and also the amount of gasket paste shall be minimized.

2.Maintain the tightening stress to be around 35 MPa. Also use ring gaskets instead of full-face gaskets, so as to ensure proper tightening stress.

3.As much as possible, use gaskets with a minimum thickness (1.5 mm or less).

▼Notes to be observed in storage

・Handle these products with care, as their sheet surface is liable to be damaged.

・Store these joint sheets in a cool and dark place not subject to direct sunshine, fresh air or ozone.

・Storage selected shall be in a clean environment, free from dust as well as from high temperature & high humidity and corrosive atmosphere.

・ If hanged on nails or the like, gaskets may suffer breakage or permanent deformation, so that they should be put between larger plates and placed horizontal for storage.