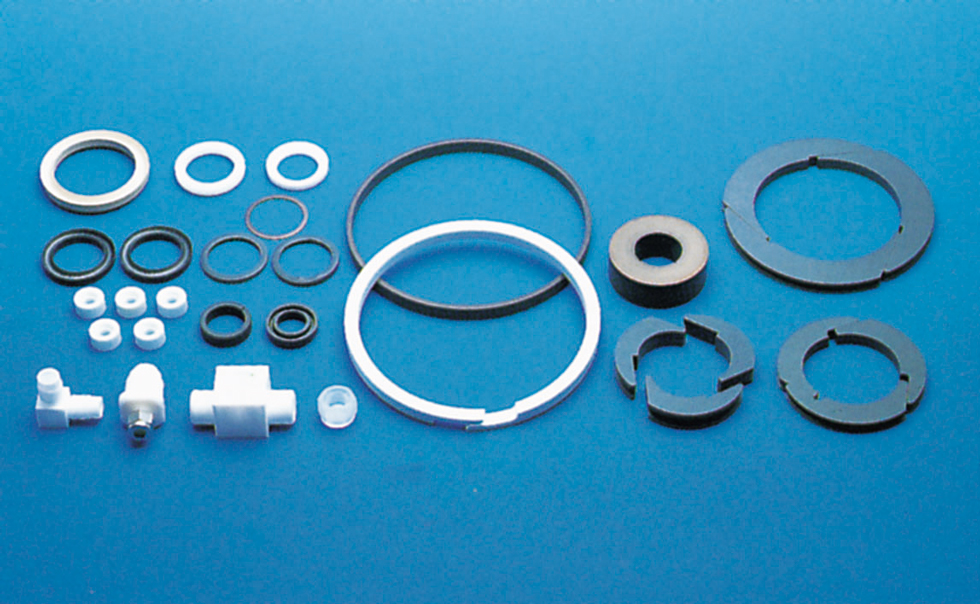

PTFE processed products

The processing of general parts are done by machine processing the molding material with a usual machine tool.

There are also processed parts that have been deformation processed. In terms of the machine processing of PTFE, it is necessary to understand the behavior of the PTFE before processing.

The following are points that need to be considered when machine processing:

(1) The thermal conductivity is small.

(2) The thermal expansion coefficient is large.

(3) There is a transition point in the room temperature that brings about a large volume change between the range of 19℃ and 23℃.

(4) There is elasticity.

(5) There are cases in which residual strain exists.

The shaping tolerance of PTFE (JIS K6884) is shown as reference.

Measurement condition: Measurement is conducted in the temperature after remaining still for 4 hours or more in a surrounding of 25±2℃.

| Classification of nominal dimension |

Allowable tolerance |

| Class 1 |

Class 2 |

| 1 and over |

16 or below |

±0.1 |

±0.3 |

| Above 16 |

40 or below |

±0.2 |

±0.6 |

| Above 40 |

63 or below |

±0.3 |

±0.8 |

| Above 63 |

100 or below |

±0.4 |

±1.0 |

| 100Above |

160 or below |

±0.5 |

±1.2 |

| 160Above |

250 or below |

±0.6 |

±1.4 |

| 250Above |

400 or below |

±0.7 |

±1.7 |

| 400Above |

630 or below |

±1.0 |

±2.0 |

| 630Above |

1000 or below |

±1.5 |

±2.5 |