Gasket Cutter

- VALQUA No.

- CUTTER

- Product name

- Gasket Cutter

- Features

- ▶ This is a set of convenient tools to easily cut out flange gaskets at a construction site or for assembly work.

▶ The supporting iron has scale marks, which allows easy and accurate size adjustments.

▶ By using a supporting iron (500L) which is sold separately, it is possible to cut out gaskets as large as 1,000 mm.

▶ It is highly recommended to keep this tool as an indispensable workshop tool not only in the maintenance department of a chemical plant, oil refinery or iron plant, but also in the assembly area of machine or equipment manufacturers as well as in pipe laying companies.

- Cutting range

- Minimum diameter : 50mm

Maximum diameter : 540mm

By using a supporting iron (500 L) which is sold separately, it is possible to cut out gaskets as large as 1,000 mm.

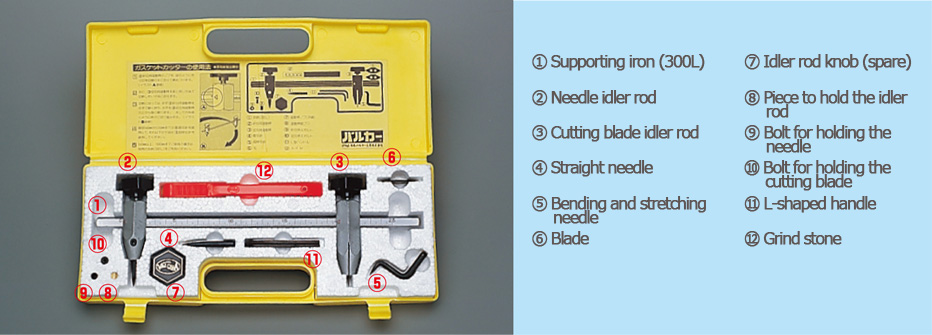

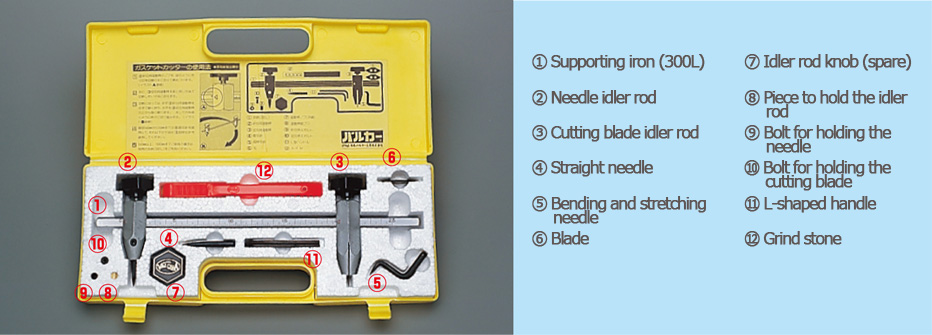

- Placing part orders

- Parts worn after long years of operation should be replaced with new parts. Orders for single items are also accepted when certain items are missing.

(For cutter blades ⑥, one replacement set consisting of five blades is available)

- Instructions for use

- 1. First, insert the straight core needle ④ or the bending type core needle ⑤ at the bottom of the floating pole of the needle core ②, and fix it using the pressure bolt for the needle core ⑨. In this case, use the bending type core needle ⑤ if the cut diameter is up to 50 mm, and use the straight core needle ④ for a cut diameter larger than 50 mm.

2. Next, at the groove of the floating pole of the cutter blade ③, attach the blade ⑥ with two pressure bolts from the cutter blade ⑩.

3. Thread the supporting iron ① into the floating pole of the needle core ② and the floating pole for the cutter blade ③.

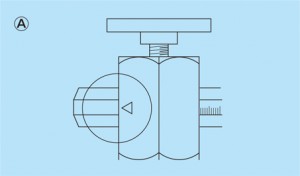

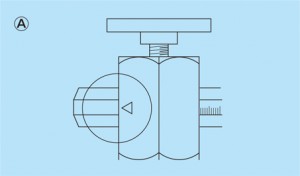

4. Set the part marked with "◁" of the floating pole of the needle core ② to zero to match the supporting iron ① as shown in Figure A, and firmly tighten with the knob.

5. Then, also shift the part marked with "◁" of the floating pole for cutter blade ③ to a desired position on the supporting iron ① determined by the radius of the gasket to be cut, and tighten firm with the knob.

6. Before cutting, place the material on a sheet of plywood board or a corrugated paper that is placed on a flat base or floor. Then, put the gasket cutter as shown in Figure B, hold the floating pole of the needle core with your left hand ②, and lightly dig in the straight core needle ④ or the bending type core needle ⑤. Now, lightly holding the floating pole for cutter blade ③ with your right hand, rotate it to cut forward while slightly pushing as if you were making a circle.